What is the thermal conductivity of graphene film?

2025-09-05 11:21:52

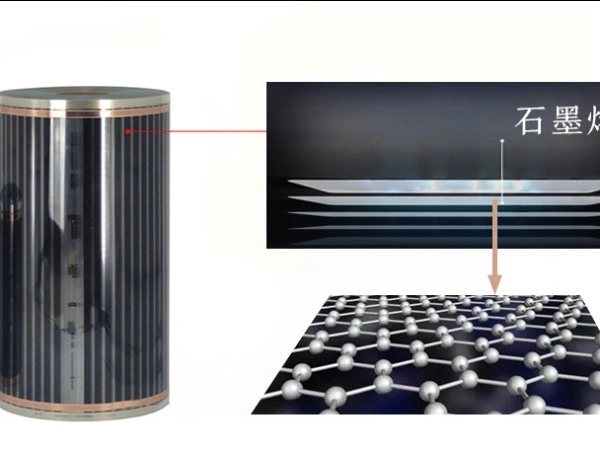

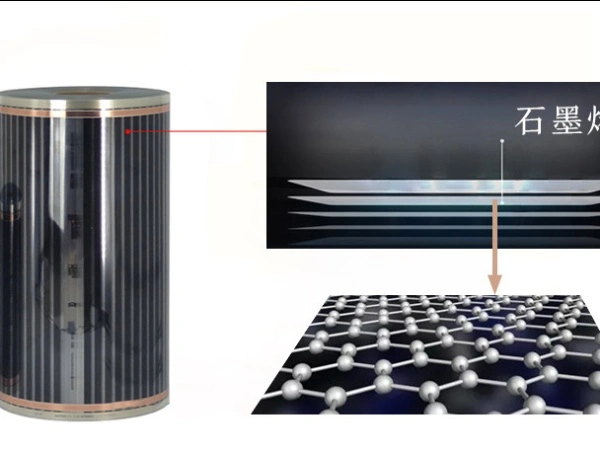

Graphene, a single layer of carbon atoms arranged in a two-dimensional hexagonal lattice, has emerged as one of the most promising nanomaterials since its isolation in 2004. Among its extraordinary properties, thermal conductivity stands out as a key characteristic driving research and industrial interest. Graphene heating films, which consist of one or more layers of graphene sheets, exhibit thermal conductivity values that far surpass those of traditional thermal management materials like copper or aluminum.

Fundamental Principles of Thermal Conductivity in Graphene Films

①Crystal Structure and Thermal Transport Mechanisms

The exceptional thermal conductivity of graphene films originates from their unique crystal structure. In a perfect graphene lattice, each carbon atom forms strong covalent sp² bonds with three adjacent atoms, creating a highly ordered, planar structure. This atomic arrangement minimizes lattice vibrations that scatter heat carriers, known as phonons. Phonons are quantized packets of vibrational energy responsible for thermal conduction in dielectric and semiconductor materials, and in graphene, they dominate heat transfer due to the material's low electron-phonon coupling at room temperature.

In single-layer graphene, phonons can travel over long distances, up to several micrometers, without significant scattering, a phenomenon known as ballistic transport. This long mean free path allows phonons to carry thermal energy efficiently across the material. When multiple graphene layers are stacked to form a film, interlayer interactions such as van der Waals forces come into play, modifying phonon dispersion relations and potentially altering thermal conductivity compared to single-layer structures.

②Phonon Modes and Thermal Conductivity Contributions

Phonons in graphene films exist in different modes, including acoustic and optical phonons. Acoustic phonons, which involve collective vibrations of the lattice, are the primary contributors to thermal conductivity due to their lower frequency and higher group velocity. Within acoustic phonons, in-plane transverse and longitudinal modes, as well as out-of-plane flexural modes, play distinct roles. Longitudinal acoustic phonons, in particular, exhibit high velocities and long mean free paths, making them major carriers of thermal energy in graphene heating films.

The thermal conductivity of graphene films is also influenced by the distribution of phonon energies. At room temperature, most phonons occupy low-energy states, which correspond to long-wavelength vibrations that scatter less frequently. This energy distribution, combined with the material's high phonon velocity, results in the ultrahigh thermal conductivity observed in high-quality graphene heating films.

While grasping the fundamental concepts establishes a basis for recognizing the heat conductivity of graphene layer, actual performance is contingent upon numerous practical aspects. These elements, which include how materials are made and structural flaws, change thermal conductivity values a lot. This is why studying them is important for both research and application development.

Key Factors Influencing Thermal Conductivity of Graphene Films

①Material Synthesis and Preparation Methods

The method used to synthesize graphene films directly impacts their thermal conductivity. Chemical vapor deposition (CVD) is a widely adopted technique for producing large-area graphene heating films. CVD-grown graphene typically exhibits high crystallinity, but factors such as growth temperature, precursor gas ratio, and substrate material can introduce defects. For example, graphene grown on copper substrates may have better uniformity than that grown on nickel, but residual impurities from the substrate can reduce thermal conductivity.

Mechanical exfoliation, the method initially used to isolate graphene, produces high-quality films with minimal defects, resulting in very high thermal conductivity values. However, this method is not scalable for industrial applications. Other techniques, such as liquid-phase exfoliation and epitaxial growth, yield films with varying degrees of crystallinity and defect density, directly affecting their thermal transport properties.

②Defects, Impurities, and Doping

Defects in graphene heating films, including point defects (e.g., vacancies, substitutional atoms), line defects (e.g., grain boundaries), and wrinkles, act as phonon scatterers, reducing thermal conductivity. Even a small number of defects can significantly shorten phonon mean free paths. For instance, grain boundaries formed during CVD growth, where separate graphene domains merge, create regions of disorder that scatter phonons and lower overall thermal conductivity.

Impurities, such as residual solvents from transfer processes or adsorbed molecules, also contribute to phonon scattering. Doping, the intentional introduction of foreign atoms to modify electrical properties, can have complex effects on thermal conductivity. Electron doping, for example, may enhance electron-phonon scattering, while certain dopants might introduce additional defect states, both of which can reduce thermal conductivity.

③Film Thickness and Layer Count

The number of graphene layers in a film, often referred to as layer count, is a critical factor in determining thermal conductivity. Single-layer graphene exhibits the highest thermal conductivity, with reported values exceeding 5000 W/m·K at room temperature under ideal conditions. As layer count increases, thermal conductivity generally decreases due to interlayer phonon scattering. In bilayer graphene, for example, thermal conductivity typically ranges from 2000 to 4000 W/m·K, depending on layer alignment and interaction strength.

Thickness variations beyond layer count, such as those caused by overlapping sheets or non-uniform deposition, can also affect thermal conductivity. Thicker films with more layers may show greater inhomogeneity, leading to localized reductions in thermal transport efficiency.

Measurement Techniques and Practical Applications of Graphene Film Thermal Conductivity

①Common Measurement Techniques

Several experimental techniques are used to measure the thermal conductivity of graphene films, each tailored to different sample sizes and material properties.Raman thermometry is a non-contact technique that utilizes the temperature sensitivity of graphene's Raman spectrum. When a laser heats up a graphene film, the G-band or 2D-band Raman peaks move in a straight line with the temperature. Researchers can figure out thermal conductivity by looking at this shift and calculating how heat moves away from an object. This method is very good for figuring out how small-area or suspended graphene heating films work.

The thermal bridge method, also known as the 3ω method, involves depositing a metal heater/thermometer on the graphene film. An alternating current passed through the heater generates periodic heating, and the resulting temperature oscillations are measured to determine thermal conductivity. This contact-based method offers high accuracy for supported films but requires careful sample preparation to ensure good thermal contact between the heater and the film.

Other techniques include time-domain thermoreflectance (TDTR), which uses ultrafast lasers to measure thermal transport over nanoscale distances, and the suspended microdevice method, where graphene heating films are suspended between heat sources and sinks to minimize substrate effects. Each method gives us a different look at thermal conductivity, and the results are typically a little different because of how the measurements were taken and the quality of the samples.

②Thermal Management

As electronic devices continue to shrink in size and increase in power density, efficient heat dissipation becomes critical to prevent performance degradation and failure. Graphene heating films can be integrated into microprocessors, light-emitting diodes (LEDs), and batteries as thermal interface materials or heat spreaders, improving heat dissipation and extending device lifetimes.

Emerging applications include thermal management in energy systems, such as lithium-ion batteries, where graphene films can help regulate temperature during charging and discharging, enhancing safety and efficiency. Additionally, graphene-based thermal composites, which combine graphene heating films with polymers or ceramics, are being developed to provide tailored thermal conductivity for specific industrial needs.

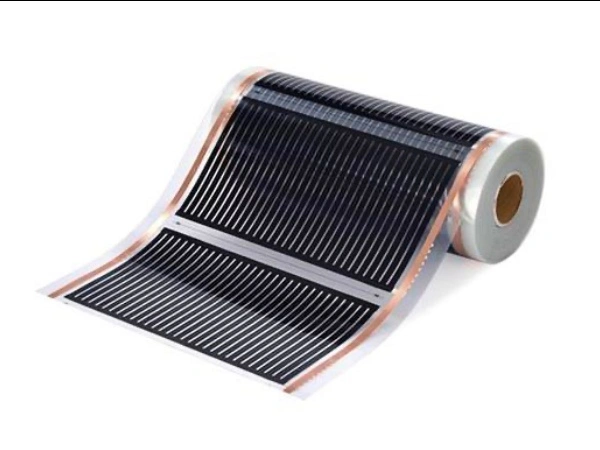

Contact Shengxihong Science

For advanced heating technologies where innovation meets efficiency, turn to Shaanxi Shengxihong Science and Technology Co., Ltd. Our graphene-based systems deliver full-surface heating through high-performance carbon nanotube films, reaching an outstanding 83% far-infrared conversion rate and an industry-leading 99.8% electrothermal conversion efficiency.

We sell a wide range of products under the "Holy Red" brand, including graphene electric heating films, electric heating artworks, heaters, smart clothing, and physiotherapy gadgets that with patent-protected and have intellectual property rights. These are backed by 17 graphene utility model patents and more than 30 awards and certifications at different levels.

We have solutions that are made just for you, whether you need comfort in your home, efficiency in your business, or something else for a specific industrial need. Contact us at 1315363763@qq.com.

References

- Novoselov, K. S., Geim, A. K., Morozov, S. V., et al. (2004). Electric field effect in atomically thin carbon films. Science, 306(5696), 666–669.

- Balandin, A. A., Ghosh, S., Bao, W., et al. (2008). Superior thermal conductivity of single-layer graphene. Nano Letters, 8(3), 902–907.

- Seol, J. H., Jo, I., Moore, A. L., et al. (2010). Two-dimensional phonon transport in supported graphene. Science, 328(5975), 213–216.

- Chen, Z., Li, X., Shi, L., et al. (2012). Thermal conductivity of graphene and graphene-based nanostructures. Advanced Materials, 24(29), 4010–4025.

- Zhang, H., Li, X., & Wang, X. (2018). CVD-grown graphene films for thermal management: Synthesis, characterization, and applications. ACS Nano, 12(5), 4291–4308.