What is graphene film?

2025-09-05 11:21:51

The arrival of graphene heating film signifies a big change from old ways of heating, with better performance and longer-lasting results.

Definition and Structural Composition of Graphene Heating Film

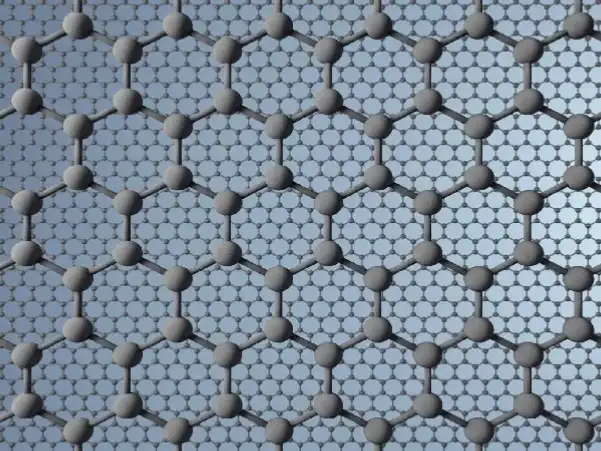

①Material Fundamentals: Graphene as the Core Component

Graphene consists of a single layer of carbon atoms arranged in a hexagonal lattice. This structure grants graphene exceptional thermal and electrical conductivity. Manufacturers incorporate graphene into heating films as a conductive layer. The material retains flexibility while maintaining structural integrity. Its atomic structure allows electrons to move freely, facilitating efficient energy transfer. Graphene outperforms traditional conductive materials like copper or nickel in both conductivity and durability. Scientists first isolated graphene in 2004, but its application in heating technology has evolved significantly since then.

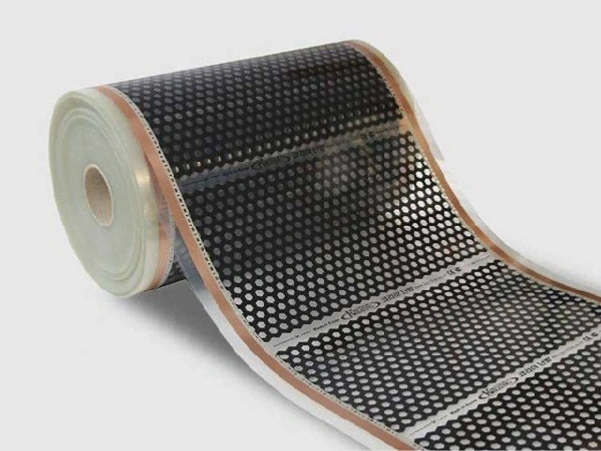

②Layered Architecture of the Heating Film

Typical graphene heating films feature multiple functional layers. A protective outer layer shields internal components from mechanical damage. An adhesive layer bonds the film to various surfaces. The graphene conductive layer sits at the core, responsible for heat generation. Insulating layers prevent heat loss and ensure safety. Each layer undergoes precise engineering to optimize performance. Manufacturers adjust layer thicknesses based on specific application requirements. The layered design balances flexibility with thermal efficiency. Proper adhesion between layers prevents delamination during use.

③Manufacturing Processes for Consistent Quality

Engineers spread graphene particles evenly over a polymer matrix. Coating machines put the mixture on top of other materials. Heat treatment makes it easier for layers to stick together and conduct electricity. Quality control checks the graphene heating films for even thickness and conductivity. Cutting operations shape the film to the right size. Advanced production methods make sure that as little material as possible is wasted. Automated systems keep an eye on manufacturing parameters to make sure they stay the same. Testing after production checks for durability and thermal performance.

Operational Principles and Technical Advantages

①Thermal Conduction Mechanisms in Graphene Films

Electric current flows through the graphene layer when connected to a power source. Electrons collide with carbon atoms, converting electrical energy into thermal energy. Phonons transmit heat across the graphene lattice efficiently. Heat spreads rapidly across the entire film surface due to graphene's high thermal conductivity. This process minimizes temperature gradients within the material. The uniform heat distribution eliminates hotspots common in traditional heating elements. Thermal conduction occurs without significant energy loss. The mechanism responds quickly to temperature adjustments.

②Electrical Performance and Safety Features

Graphene heating films operate at low voltages compared to conventional heaters. Their electrical resistance remains stable over extended use. Built-in overheat protection systems monitor temperature levels continuously. Insulating layers stop electrical leaks and short connections. Following international safety standards keeps users safe. The films keep working well over a wide range of temperatures. Electrical parts are put through a lot of tests to make sure they are reliable. Safety certifications prove that they can be used in homes and businesses. Installing it correctly makes electrical safety even better.

③Energy Efficiency and Environmental Benefits

High conversion rates transform over 95% of electrical energy into heat. This efficiency reduces overall energy consumption significantly. Lower energy use translates to reduced carbon emissions. The films require minimal power to maintain desired temperatures. Their rapid heating capability minimizes standby energy loss. Long operational lifespans reduce replacement frequency and material waste. Compatibility with renewable energy sources enhances sustainability. Energy savings accumulate across residential, commercial, and industrial applications. Environmental impact assessments consistently rate graphene heating films as eco-friendly alternatives.

With established principles and advantages, graphene heating film finds applications across diverse industries.

Applications and Market Development Trends

①Residential and Commercial Heating Solutions

Underfloor heating systems integrate graphene films beneath various flooring materials. Wall-mounted panels provide targeted room heating with slim profiles. Window defogging applications prevent condensation efficiently. Homeowners appreciate zoned heating capabilities for personalized comfort. Commercial spaces benefit from uniform heating without unsightly radiators. Easy installation adapts to existing building structures. Smart thermostat integration enables precise temperature control. Energy-efficient operation reduces utility costs for property owners. Retrofit applications upgrade older buildings effectively. User feedback highlights improved comfort and reduced energy bills.

②Industrial and Specialized Applications

Manufacturing processes use graphene films for controlled heating in production lines. Agricultural settings maintain optimal temperatures for plant growth and livestock comfort. Medical equipment incorporates heating films for patient warming systems. Automotive sectors use them in parts for heating and defrosting seats. Their small weight makes them useful for heat control in aerospace. Food processing plants use them to store food at the right temperature. Precise heating is good for labs. Industrial designers like how flexible they are for custom uses. Reliability of performance serves important operational needs.

③Market Growth Drivers and Future Innovations

The increasing cost of energy pushes demand for more efficient heating solutions. Government sustainability initiatives promote adoption of eco-friendly technologies. Advancements in manufacturing reduce production costs gradually. Expanding application ranges open new market segments continuously. The increase in the residential market is due to people's understanding of energy efficiency. Partnerships between businesses speed up the process of bringing innovative applications to market. Market analysts project consistent annual growth rates exceeding 20% through 2030. Emerging markets in developing regions show increasing adoption rates.

Contact Shengxihong Science

For cutting-edge heating solutions that blend innovation with efficiency, look no further than Shaanxi Shengxihong Science and Technology Co., Ltd. As a leading scientific and technological innovation enterprise integrating R&D, production, sales, and service, we've redefined heating technology through our advanced solutions: our graphene heating films feature full surface heating powered by high-performance carbon nanotube heating films, boasting an impressive 83% far-infrared conversion efficiency and an extraordinary 99.8% electrothermal conversion efficiency, setting new standards for energy-saving and uniform heating.

Our diverse "Holy Red" product portfolio, including graphene electric heating films, electric heating paintings, electric heaters, clothing, and physiotherapy products, all come with independent intellectual property rights and patents. Backed by 17 graphene utility model patents and over 30 honorary certificates at all levels, our innovations stand as a testament to our commitment to quality and technological excellence.

Whether you're seeking residential, commercial, or specialized heating products, reach out to us today at 1315363763@qq.com.

References

- Novoselov, K. S., Geim, A. K., Morozov, S. V., et al. (2004). Electric field effect in atomically thin carbon films. Science, 306(5696), 666-669.

- Balandin, A. A., Ghosh, S., Bao, W., et al. (2008). Superior thermal conductivity of single-layer graphene. Nano Letters, 8(3), 902-907.

- Wang, H., Zhang, L., & Liu, Z. (2018). Graphene-based flexible heating films: Materials, structures, and applications. Advanced Materials Technologies, 3(9), 1800197.

- Smith, J. D., & Johnson, R. K. (2020). Energy efficiency analysis of graphene heating systems in residential buildings. Energy Policy, 145, 111745.

- Global Graphene Heating Film Market Report (2023). Market Research Future.