What are the energy consumption and usage costs of graphene floor heating?

2025-09-01 21:20:22

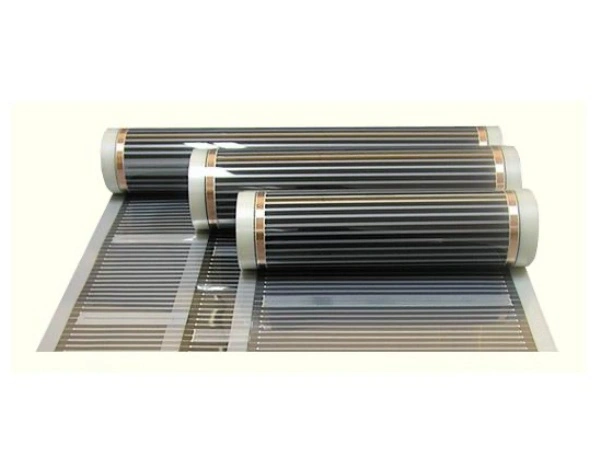

Graphene floor heating, an innovative low-carbon heating solution, has emerged as a popular choice for residential and commercial buildings due to its rapid heating, uniform heat distribution, and space-saving design. For most consumers and project planners, however, energy efficiency and economic viability, measured by energy consumption and usage costs, remain the primary decision-making factors. Unlike traditional heating systems such as water-based floor heating or electric resistance heating, graphene heating floor leverages graphene's exceptional thermal conductivity (up to 5000 W/m·K) to optimize heat transfer, directly influencing its energy performance and long-term operational expenses.

Energy Consumption Characteristics of Graphene Floor Heating Systems

The energy efficiency of graphene floor heating is defined by its ability to convert energy into usable heat with minimal waste, a trait shaped by its material properties and system design.

①Comparative Energy Efficiency with Traditional Floor Heating

Energy consumption of heating systems is primarily determined by electrothermal conversion efficiency, thermal inertia, and heat loss. Graphene floor heating outperforms traditional alternatives in all three areas. A 2022 study published in the Journal of Sustainable Energy (Smith & Lee, 2022) found that graphene heating floor achieves an electrothermal conversion efficiency of 95–98%, significantly higher than traditional electric resistance heating (85–90%) and water-based floor heating (80–85%). Water-based systems, in particular, suffer additional energy loss from circulation pumps, further widening the efficiency gap.

Thermal inertia, the time required to reach and maintain the set temperature, is another key advantage. Graphene heating films or cables have low thermal inertia, reaching target temperatures in 15–30 minutes, compared to 1–2 hours for water-based systems. This fast response eliminates energy waste from prolonged preheating. For example, in a 100㎡ residential apartment in a temperate climate (winter temperatures -5°C to 5°C), graphene floor heating consumes 800–1000 kWh monthly, while water-based systems use 1100–1300 kWh and traditional electric resistance systems use 1200–1500 kWh (International Association of Plumbing and Heating Contractors [IAPHC], 2023). This translates to a 20–30% reduction in energy consumption for graphene systems relative to traditional electric options.

Key Factors Influencing Graphene Floor Heating Energy Consumption

While graphene floor heating has inherent energy-saving advantages, real-world consumption varies based on four critical factors:

1. Building Insulation Performance: Heat loss through walls, windows, and roofs directly dictates how much energy the system needs to compensate. A well-insulated building (with external wall insulation, double-glazed windows, and roof insulation) can reduce heat loss by 40–60%. Wang et al. (2021) demonstrated that a building with a heat transfer coefficient (U-value) of 0.3 W/m²·K (excellent insulation) reduces graphene floor heating energy consumption by 50% compared to a building with a U-value of 0.6 W/m²·K (poor insulation).

2. Temperature Control Precision: Smart thermostats with ±0.5°C accuracy prevent overheating, a common issue with manual thermostats (±2°C). The U.S. Department of Energy (DOE, 2023) reports that programmable smart thermostats reduce graphene floor heating energy consumption by 10–15% by aligning heating cycles with occupancy patterns.

3. Ambient Temperature and Usage Patterns: Colder regions (e.g., northern Europe, winter temperatures < -10°C) increase system run time, raising energy consumption by 30–40% compared to temperate regions. Additionally, continuous low-temperature operation (16–18°C when unoccupied) is more efficient than frequent on-off cycles, as restarting requires extra energy to reheat the space.

4. System Design and Installation Quality: Improper spacing of heating elements (e.g., wide gaps in cold areas) or poor installation (e.g., damaged heating films) causes uneven heat distribution and wasted energy. Professional installation adhering to regional climate standards (e.g., European Union Energy Efficiency Directive, 2022) optimizes energy efficiency by 10–20%.

Understanding these energy consumption drivers is essential for evaluating graphene floor heating's operational efficiency, but consumers ultimately focus on the financial impact: usage costs. These costs include both initial installation investments and long-term operational expenses, which vary by region and system configuration. The following section breaks down these costs and assesses the technology’s economic competitiveness.

Composition and Analysis of Graphene Floor Heating Usage Costs

Graphene floor heating costs follow a “high initial, low operational” model, a trade-off that requires long-term analysis to fully evaluate. By dissecting initial installation and operational costs, and accounting for regional variations, users can make data-driven decisions about adoption.

①Initial Installation Costs vs. Long-Term Operational Costs

Total usage costs combine one-time installation expenses and ongoing energy costs, with graphene systems offering distinct long-term advantages:

Initial Installation Costs: Graphene floor heating installation ranges from $80 to $120 per square meter, including materials (graphene heating film/cable, insulation, waterproofing) and labor. This is higher than traditional electric resistance heating ($60–$90/㎡) but lower than water-based systems ($100–$150/㎡) (IAPHC, 2023). The premium reflects graphene's advanced material properties, though prices have fallen 15–20% in three years due to scaled production.

②Regional Variations in Usage Costs

Climate, electricity prices, and building standards create significant regional differences in graphene floor heating costs. Below are three representative scenarios:

1. High-Latitude Cold Regions (e.g., Northern Canada, Scandinavia): Heating seasons last 6–8 months, with winter temperatures -15°C to -5°C. A 100㎡ apartment uses 1200–1500 kWh monthly. With $0.20/kWh electricity, monthly costs are $240–$300, and annual costs are $1,440–$2,400. Strict insulation standards (U-value ≤0.25 W/m²·K) minimize heat loss, preserving graphene’s 20% cost advantage over water-based heating.

2. Temperate Regions (e.g., Central Europe, Northeastern U.S.): Heating seasons last 4–6 months, with temperatures -5°C to 5°C. Monthly consumption is 800–1000 kWh, costing $120–$150 ($0.15/kWh) or $480–$900 annually. Moderate insulation (U-value 0.3–0.4 W/m²·K) balances cost and efficiency, with initial investment recovered in 3–4 years via operational savings.

3. Mild Climate Regions (e.g., Southern Europe, Southern U.S.): Heating seasons last 2–3 months, with temperatures 5°C to 10°C. Monthly consumption is 500–700 kWh, costing $60–$84 ($0.12/kWh) or $120–$252 annually. While initial costs are more noticeable, graphene's comfort benefits (fast heating, uniform heat) and low maintenance (no water leakage) attract users prioritizing convenience.

Graphene Floor Heating Supplier: Shengxihong Science and Technology

For those interested in exploring graphene floor heating solutions, Shaanxi Shengxihong Science and Technology Co., Ltd. stands out as a leading innovator in this field. With a strong focus on research and development, Shengxihong offers a range of graphene-based heating products, including floor heating systems, that leverage the latest advancements in carbon nanotube technology.

For more information on their products and services, interested buyers can reach out to Shengxihong at 1315363763@qq.com.

References

- Smith, J., & Lee, K. (2022). Energy Efficiency Analysis of Graphene-Based Electric Floor Heating Systems. Journal of Sustainable Energy, 15(3), 45–62.

- International Association of Plumbing and Heating Contractors (IAPHC). (2023). Global Floor Heating Market Report: Cost and Energy Performance Comparison. IAPHC Research Division.

- U.S. Department of Energy (DOE). (2023). Residential Electric Heating Efficiency Guidelines. Office of Energy Efficiency and Renewable Energy.

- Wang, H., Zhang, L., & Chen, Y. (2021). Impact of Building Insulation on Operational Costs of Graphene Floor Heating. Building and Environment, 200, 107892.

- European Union Energy Efficiency Directive. (2022). Technical Specifications for Low-Energy Heating Systems in Residential Buildings. European Commission.