Three Forms Of Graphene Films

2025-09-01 21:01:45

Graphene, a single layer of carbon molecules orchestrated in a hexagonal cross section, has revolutionized materials science with its uncommon mechanical, electrical, and warm properties. Among its different shapes, graphene films,engineered structures composed of graphene or graphene-derived materials, have risen as flexible stages for applications extending from gadgets to vitality capacity. This article investigates three unmistakable shapes of graphene warming movies, each characterized by its union strategy, auxiliary characteristics, and useful properties. By looking at chemical vapor statement (CVD) graphene movies, graphene oxide (GO) movies, and composite graphene films.

CVD-Grown Graphene Films: High-Purity Monolayer and Multilayer Structures

①Synthesis via Chemical Vapor Deposition

Chemical vapor testimony (CVD) is the essential strategy for creating high-quality graphene movies, especially those requiring consistency and negligible surrenders. The prepare includes uncovering a catalytic metal substrate (regularly copper or nickel) to hydrocarbon gasses (such as methane) at tall temperatures (800–1100°C). Beneath these conditions, hydrocarbon particles break down, discharging carbon iotas that diffuse over the metal surface and self-assemble into a single layer of graphene. For multilayer movies, the handle is rehashed with controlled cooling rates to energize layer-by-layer development. Post-synthesis, the graphene film is frequently exchanged to a target substrate (e.g., silicon dioxide, polymers) by carving absent the metal catalyst, guaranteeing the film holds its auxiliary integrity.

②Structural and Functional Attributes

CVD-grown graphene movies are prized for their tall crystallinity and moo deformity thickness, which interpret to uncommon electrical conductivity (up to 10⁶ S/m) and warm conductivity (roughly 5000 W/m·K). Monolayer CVD movies are molecularly lean (0.34 nm) however display exceptional mechanical quality, with a Young's modulus surpassing 1 TPa. Multilayer movies, whereas marginally thicker (each extra layer includes ~0.34 nm), keep up most of these properties whereas advertising improved toughness, making them appropriate for applications requiring rehashed mechanical push. Their transparency, typically 97.7% for monolayers, encourage grows their utility in optoelectronic devices.

③Key Applications in Advanced Technologies

The virtue and execution of CVD graphene movies make them perfect for high-tech applications. In gadgets, they serve as straightforward conductive cathodes in adaptable shows, supplanting indium tin oxide (ITO) due to their prevalent adaptability and lower fetched over time. In vitality frameworks, they upgrade the effectiveness of sun powered cells by moving forward light retention and charge carrier transport. Moreover, their biocompatibility has driven to utilize in biomedical sensors, where they distinguish diminutive concentrations of biomolecules with tall affectability. In spite of their preferences, CVD movies stay moderately costly to deliver at scale, restricting their selection in cost-sensitive industries. CVD-grown graphene films speak to the gold standard for high-performance applications, but their blend complexity and taken a toll have driven the advancement of elective shapes. Chief among these is graphene oxide film, a solution-processable fabric that prioritizes flexibility and reasonableness over purity.

Graphene Oxide Films: Solution-Processable and Chemically Tunable Structures

①Synthesis from Graphite Oxide

Graphene oxide (GO) movies are inferred from graphite oxide, delivered by means of chemical oxidation of graphite utilizing solid oxidizing operators (e.g., sulfuric corrosive, potassium permanganate). This handle presents oxygen-containing utilitarian bunches (hydroxyl, epoxy, carboxyl) onto the graphite layers, debilitating interlayer bonds and empowering shedding into person GO sheets by means of ultrasonic treatment in water or natural solvents. GO movies are at that point shaped by storing these fluid or solvent-based scatterings onto substrates utilizing methods like turn coating, drop casting, or vacuum filtration, taken after by drying to expel the fluid stage. This solution-based approach permits for large-area generation at a division of the taken a toll of CVD films.

②Chemical Versatility and Structural Adaptability

Unlike CVD graphene, GO movies are electrically protection due to the disturbance of the sp² carbon grid by oxygen bunches. In any case, this chemical usefulness is a key advantage: the utilitarian bunches empower simple alteration through chemical responses, such as decrease (to shape decreased graphene oxide, rGO) or functionalization with polymers, metals, or biomolecules. Reduction,achieved through warm, chemical, or photochemical medicines, somewhat reestablishes the sp² grid, rendering rGO movies conductive (10²–10⁴ S/m), yet less so than CVD graphene. GO movies are moreover profoundly hydrophilic, making them congruous with water-based handling, and their layered structure permits for controlled porosity, valuable in filtration applications.

③Practical Uses in Industrial and Consumer Products

The reasonableness and processability of GO movies make them appropriate for a run of mechanical applications. In water treatment, their permeable, functionalized structure empowers productive evacuation of overwhelming metals and natural toxins. As boundary movies, they give great gas and fluid impermeability when kept on polymers, upgrading the rack life of nourishment bundling. In vitality capacity, rGO movies serve as cathodes in supercapacitors, advertising tall capacitance due to their huge surface region. Customer items, such as conductive inks for printed hardware and anti-corrosion coatings for metals, too use GO's tunable properties.

Whereas less conductive than CVD movies, GO's flexibility and moo taken a toll make it crucial in numerous commercial contexts. Graphene oxide movies exceed expectations in applications requiring chemical tunability and low-cost generation, but their electrical and mechanical impediments have impelled advancement in a third shape: composite graphene films, which combine graphene with other materials to synergistically improve performance.

Composite Graphene Films: Synergistic Multimaterial Composites

①Composition and Fabrication Strategies

Composite graphene movies coordinated graphene (or GO/rGO) with other materials,polymers, metals, ceramics, or carbon nanotubes,to address the shortcomings of unadulterated graphene movies. Creation strategies change based on the lattice fabric: polymer composites are regularly shaped by blending graphene scatterings with polymer arrangements, taken after by casting or expulsion; metal composites may include electrodeposition of metals onto graphene substrates; and ceramic composites can be synthesized through sol-gel forms. The objective is to make a fabric where graphene upgrades the matrix's properties (e.g., conductivity, quality) whereas the lattice progresses graphene's processability or steadiness. For illustration, including graphene to polyimide movies increments warm conductivity without relinquishing adaptability, whereas inserting graphene in copper movies improves electrical conductivity and erosion resistance.

②Synergistic Property Enhancements

Composite graphene movies coordinated graphene (or GO/rGO) with other materials,polymers, metals, ceramics, or carbon nanotubes,to address the shortcomings of unadulterated graphene movies. Creation strategies change based on the lattice fabric: polymer composites are regularly shaped by blending graphene scatterings with polymer arrangements, taken after by casting or expulsion; metal composites may include electrodeposition of metals onto graphene substrates; and ceramic composites can be synthesized through sol-gel forms. The objective is to make a fabric where graphene upgrades the matrix's properties (e.g., conductivity, quality) whereas the lattice progresses graphene's processability or steadiness. For illustration, including graphene to polyimide movies increments warm conductivity without relinquishing adaptability, whereas inserting graphene in copper movies improves electrical conductivity and erosion resistance.

③Broad Industrial Adoption and Scalability

Composite graphene films have found far reaching utilize over businesses due to their adjusted execution and versatility. In car designing, they strengthen lightweight materials like carbon fiber, progressing basic keenness whereas decreasing fuel utilization. In aviation, they serve as heat-resistant coatings for flying machine components, leveraging their warm soundness. Buyer gadgets advantage from their utilize in battery cathodes, where graphene-silicon composites increment vitality thickness by 30–40% compared to conventional graphite cathodes. The development segment employments graphene-cement composites to improve concrete toughness, diminishing splitting and amplifying framework life expectancy. Not at all like unadulterated graphene movies, composites can be created utilizing existing fabricating gear, bringing down boundaries to selection and empowering large-scale generation at competitive prices.

Conclusion

The three shapes of graphene films, CVD-grown, graphene oxide, and composite, each offer special focal points that cater to unmistakable application needs. CVD movies stand out for their tall virtue and execution, making them fundamental in progressed hardware and vitality advances. Graphene oxide movies prioritize reasonableness and chemical tunability, driving advancement in water treatment, bundling, and printed hardware. Composite movies, through synergistic fabric integration, bridge execution crevices, empowering far reaching mechanical utilize in car, aviation, and development. Together, these shapes highlight graphene's flexibility as a useful fabric, with continuous inquire about proceeding to grow their capabilities and decrease generation costs. As understanding of their properties extends, graphene movies are balanced to play an progressively central part in next-generation innovations and ordinary products.

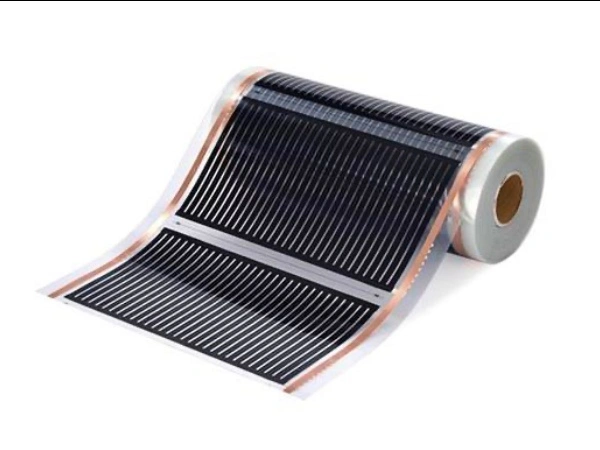

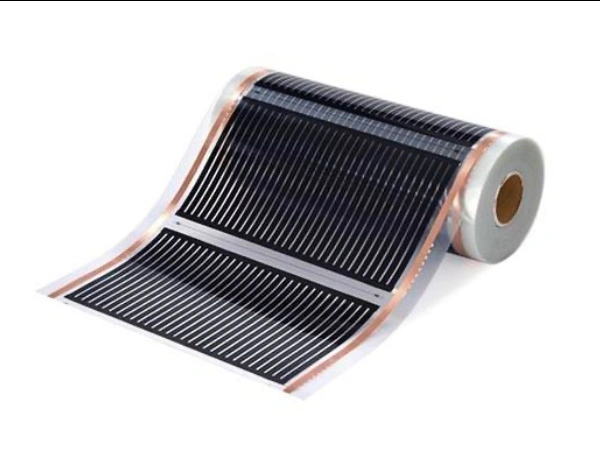

Shengxihong Science and Innovation Co., Ltd creates, produces and offers the taking after items: Graphene sauna room, Graphene cold-resistant air-conditioner, Graphene electric warming film, Graphene electric warming portray, Graphene electric radiator, Graphene physical treatment clothing, Graphene electric cover, and Graphene car cleverly warming situate pad beneath the brand title of "Shengxihong". All the items recorded for deal have autonomous mental property rights and licenses. The company has gotten 17 graphene utility show licenses and won more than 30 privileged certificates at all levels. Contact e-mail: 1315363763@qq.com.

References

- Geim, A. K., & Novoselov, K. S. (2007). "The rise of graphene." Nature Materials, 6(3), 183–191.

- Li, X., et al. (2009). "Large-area synthesis of high-quality and uniform graphene films on copper foils." Science, 324(5932), 1312–1314.

- Stankovich, S., et al. (2006). "Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide." Carbon, 45(7), 1558–1565.

- Zhang, M., et al. (2018). "Graphene-based composite films: Preparation, properties, and applications." Progress in Materials Science, 93, 331–372.

- International Graphene Institute. (2021). "Graphene Film Standards and Characterization Guidelines." University of Manchester Press.