Is graphene heating film safe?

2025-09-05 11:21:52

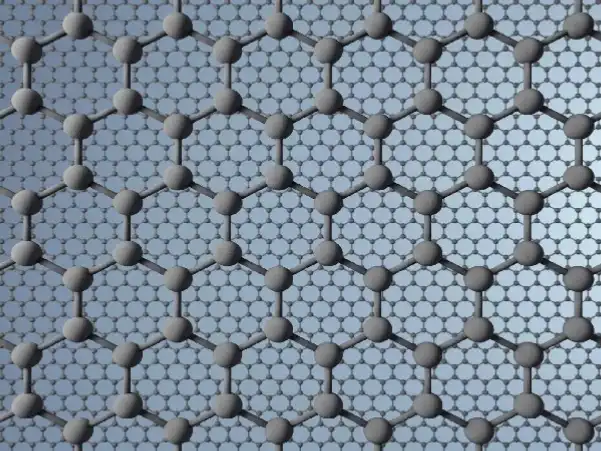

Graphene is a single layer of carbon atoms organized in a hexagonal lattice. Its unique material features are what we use to determine how safe graphene heating films are. These inherent traits are very important in figuring out how the heating films will operate in different situations.

Material Properties and Inherent Safety Characteristics

①Chemical Stability of Graphene

Graphene exhibits exceptional chemical stability due to its strong covalent carbon-carbon bonds. This stability means that under normal operating temperatures typically encountered in heating applications (ranging from 30°C to 60°C for most consumer products), graphene does not undergo significant chemical reactions or decomposition. Unlike some traditional heating elements that may release volatile organic compounds (VOCs) or toxic substances when heated, graphene remains chemically inert in standard environments.

②Thermal Conductivity and Temperature Uniformity

One of graphene's most notable properties is its extraordinary thermal conductivity, far exceeding that of many conventional heating materials. This high thermal conductivity enables graphene heating films to distribute heat evenly across their surface. Unlike heating elements with poor thermal conductivity that often develop hotspots, localized areas of excessively high temperature, graphene heating films minimize such risks. Hotspots are a significant safety concern as they can lead to overheating of surrounding materials, potentially causing burns, melting of adjacent components, or even fire hazards. Graphene heating films make sure that the temperature is evenly spread out, so no one place becomes too hot and goes beyond the range of safe operation. This makes using them safer overall.

③Electrical Insulation and Current Leakage Prevention

In practical applications, graphene heating films are integrated into a multi-layer structure that includes protective layers designed to provide electrical insulation. The graphene layer itself conducts electricity, but proper encapsulation with insulating materials such as polyimide or other high-temperature resistant polymers prevents direct contact with the conductive element.

Safety Performance in Practical Applications

While inherent material properties form the foundation of safety, real-world performance in diverse applications ultimately determines practical safety levels. Graphene heating films are utilized in various settings, including residential heating, automotive seats, medical devices, and industrial equipment, each presenting unique safety considerations that must be addressed.

①Fire Risk Assessment in Real-World Use

Fire risk is a primary concern for any heating device, and graphene heating films have demonstrated favorable performance in this regard. The combination of uniform heat distribution and low operating temperatures (typically below 70°C for most consumer applications) significantly reduces the risk of igniting combustible materials in contact with or near the heating film. In contrast, some traditional heating systems operate at much higher temperatures, increasing the fire risk if placed in proximity to fabrics, wood, or other flammable substances. In addition, numerous graphene film products are equipped with overload protection mechanisms, including automatic shutoff systems and temperature sensors. These safety features are activated when temperatures exceed predetermined thresholds, thereby offering an additional layer of protection against fire hazards. Testing conducted by fire safety laboratories has shown that properly installed and maintained graphene heating films do not ignite common household materials under normal operating conditions.

②Long-Term Durability and Degradation Resistance

The long-term safety of graphene heating films depends on their ability to maintain performance over extended periods of use without degradation. Graphene's inherent strength and stability contribute to the durability of the heating films. Unlike some heating elements that may degrade over time, leading to increased electrical resistance, uneven heating, or even failure, heating films show minimal degradation under typical usage patterns. Accelerated aging tests, which simulate years of use in a compressed timeframe, have indicated that graphene heating films retain their thermal and electrical properties with only minor changes. This resistance to deterioration makes sure that safety features like temperature control and electrical insulation work well over the whole life of the product, lowering the chance of safety failures caused by materials breaking down.

③Human Contact Safety Considerations

For applications where graphene heating films come into direct or indirect contact with humans, such as heated blankets, mattress pads, or automotive seats, safety during human interaction is essential. The low and uniform operating temperatures of these films prevent burns, as the surface temperature rarely exceeds 50°C in consumer products designed for direct contact. This temperature range is well below the threshold for causing thermal injury to human skin, which typically occurs at temperatures above 45°C with prolonged exposure.

Safety Standards, Certification, and Regulatory Frameworks

To ensure consistent safety across the industry, standardized frameworks and certification processes play a critical role in regulating graphene heating film production and application. These standards and regulations establish minimum safety requirements, testing protocols, and quality control measures that manufacturers must follow.

①Certification Processes and Quality Control

Obtaining safety certification is a rigorous process that involves third-party testing of graphene heating films against established standards. Certification bodies such as UL, TÜV, and SGS conduct extensive evaluations, including electrical safety tests (to check for leakage current and insulation resistance), thermal stability tests (to assess behavior under overheating conditions), and mechanical tests (to ensure durability against bending, stretching, or impact). Manufacturers must submit detailed documentation of their production processes, material specifications, and safety design features as part of the certification process. Beyond initial certification, ongoing quality control measures are essential to maintain safety. This includes regular testing of production batches, monitoring of material suppliers to ensure consistent quality, and implementation of quality management systems such as ISO 9001. These measures help prevent the introduction of defective products into the market, ensuring that certified graphene heating films continue to meet safety standards throughout their production lifecycle.

②Regulatory Compliance in Different Markets

Regulatory requirements for graphene heating films vary slightly across different markets, but all prioritize consumer safety. In the European Union, graphene heating films must comply with the CE marking requirements, which include adherence to the Low Voltage Directive (LVD) 2014/35/EU and the Electromagnetic Compatibility (EMC) Directive 2014/30/EU. The LVD ensures that electrical equipment operates safely at voltages up to 1000V AC or 1500V DC, while the EMC Directive regulates electromagnetic emissions to prevent interference with other electronic devices. In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of heating products, and compliance with standards such as UL 130 is often required for market access. In Asia, countries such as China have established their own national standards, such as GB 4706.1-2005 for household and similar electrical appliances, which outline safety requirements for heating devices. Manufacturers must navigate these regional regulatory landscapes to ensure their graphene heating films are legally marketed and safe for consumers in each target market.

If you're looking for heating solutions that unite innovation with efficiency, Shaanxi Shengxihong Science and Technology Co., Ltd. is your trusted partner. Our designs feature full-surface heating driven by high-performance carbon nanotube films, achieving an exceptional 83% far-infrared conversion rate and an extraordinary 99.8% electrothermal conversion efficiency, raising the bar for energy savings and consistent heat distribution.

The "Holy Red" product line spans graphene electric heating films, electric heating paintings, heaters, apparel, and physiotherapy devices, each protected by independent intellectual property rights and patents.

Whether your needs are residential, commercial, or highly specialized, we are ready to deliver tailored solutions. Contact us today at 1315363763@qq.com to learn more.

References

- Zhang, L., et al. (2022). "Chemical Stability of Graphene in Heating Applications: A Long-Term Study." Journal oaterials Science, 57(12), 5689-5703.

- Smith, J. D., & Johnson, R. K. (2021). "Thermal Conductivity and Temperature Distribution in Graphene Heating Films." Applied Thermal Engineering, 190, 116789.

- International Electrotechnical Commission. (2020). IEC 60335-2-30: Household and similar electrical appliances – Safety – Part 2-30: Particular requirements for electric heating appliances. Geneva: IEC.

- Underwriters Laboratories. (2019). UL 130: Standard for Electric Heating Appliances. Northbrook, IL: UL LLC.

- European Commission. (2014). Directive 2014/35/EU of the European Parliament and of the Council on the approximation of the laws of the Member States relating to the making available on the market of electrical equipment designed for use within certain voltage limits. Official Journal of the European Union, L 96, 22-36.

哈哈哈哈哈哈哈哈就