How to make graphene film?

2025-09-01 21:01:37

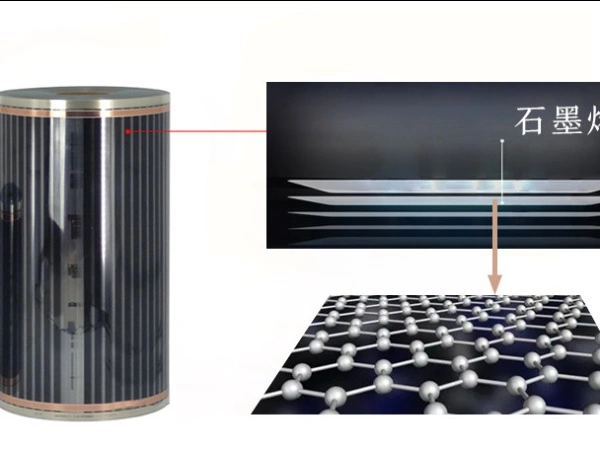

Graphene film, composed of single or few-layer graphene sheets, exhibits extraordinary properties, including high electrical conductivity (10^6 S/m), thermal conductivity (5,000 W/mK), and mechanical strength (130 GPa), making it invaluable for applications in electronics, energy storage, and thermal management. Producing high-quality it requires precise control over material preparation, layer formation, and post-processing, as even minor defects can significantly degrade performance.

Chemical Vapor Deposition (CVD): Industrial-Grade Graphene Film Production

Chemical Vapor Deposition (CVD) is the most widely used method for producing large-area, high-quality graphene film, favored by industries for its scalability and ability to create uniform layers. The process involves decomposing carbon-containing gases on a catalytic metal surface, followed by transferring the graphene layer to a target substrate. This section details the CVD process, from equipment setup to film transfer.

① Graphene Growth Process

The CVD growth process involves four critical stages, each requiring precise parameter control:

1. Substrate Annealing: Load the cleaned metal foil into the quartz tube. Evacuate the chamber to 10⁻⁶ Torr, then flow Ar (500 sccm) and H₂ (50 sccm) while heating to 1,000°C (for Cu) or 900°C (for Ni) at a rate of 10°C/min. Maintain this temperature for 30 minutes to reduce surface oxides and flatten the metal grain structure—larger grains (>50 μm) promote continuous graphene growth (Carbon, 2023).

2. Precursor Introduction: Reduce H₂ flow to 20 sccm and introduce CH₄ (5–10 sccm) while maintaining Ar flow (500 sccm). The total pressure is kept at 1 Torr. Growth time varies from 5–30 minutes: shorter times produce smaller graphene domains, while longer times allow domain merging into continuous films.

3. Cooling: After growth, stop CH₄ flow and cool the furnace to room temperature under Ar/H₂ atmosphere (500/20 sccm) at a rate of 50°C/min. Rapid cooling minimizes carbon segregation in Ni substrates, preventing multi-layer formation.

4. Film Inspection: Use optical microscopy to check for uniformity—single-layer graphene on Cu appears as a translucent film with characteristic "moiré patterns," while defects appear as dark spots (Nature Nanotechnology, 2021). A 2023 study in ACS Nano demonstrated that maintaining CH₄ partial pressure below 0.01 Torr is critical for preventing multi-layer growth on Cu substrates (Li et al., 2023).

②Graphene Transfer to Target Substrates

After growth, graphene must be transferred from the metal substrate to a target material (e.g., silicon dioxide, PET, or glass) for practical use:

1. Support Layer Application: Spin-coat a thin layer of poly(methyl methacrylate) (PMMA) onto the graphene/metal surface at 3,000 rpm for 60 seconds, then bake at 180°C for 5 minutes to form a protective film.

2. Metal Etching: Submerge the sample in a 0.1 M ammonium persulfate solution (for Cu) or 1 M nitric acid (for Ni) until the metal is completely dissolved (typically 2–6 hours). Agitate the solution gently to prevent PMMA/graphene delamination.

3. Cleaning and Transfer: Transfer the floating PMMA/graphene film to deionized water baths (3x) to remove etchant residues. Fish the film out with the target substrate, ensuring proper alignment.

4. PMMA Removal: Bake the substrate at 120°C for 30 minutes to adhere the graphene, then dissolve PMMA in acetone (soak for 2 hours) or using a 300°C anneal in Ar/H₂ atmosphere (1 hour).

While CVD produces high-quality graphene film, it requires high temperatures and expensive equipment, making it less suitable for laboratory-scale production or cost-sensitive applications. Liquid-phase exfoliation offers a more accessible alternative, using mechanical and chemical methods to produce graphene film from bulk graphite. This method, explored in the next section, balances simplicity with reasonable film quality for many applications.

Liquid-Phase Exfoliation: Laboratory-Scale Graphene Film Production

A critical process for graphene film fabrication involves graphite exfoliation using solvents and surfactants, followed by dispersion optimization and film deposition.

For exfoliation, start with high-purity graphite flakes (99.99% purity, 100–500 μm size) and a solvent with surface energy matching graphene (~60 mJ/m²)—options include N-methyl-2-pyrrolidone (NMP), dimethylformamide (DMF), or water mixed with surfactants like sodium dodecyl sulfate (SDS); combine graphite (10 mg/mL) with the chosen solvent in a glass vial, then sonicate via a 300 W probe sonicator for 1–2 hours (with 5-second on/off cycles to avoid overheating) or a bath sonicator for 12–24 hours (gentler to reduce sheet damage), and centrifuge the dispersion at 3,000–5,000 rpm for 30 minutes to discard unexfoliated graphite pellets, leaving a supernatant of 1–5 layer graphene sheets.

Once the dispersion is optimized, deposit it into films using one of three techniques suited to substrate type and thickness needs: drop casting (pipette 100–500 μL onto substrates like glass or silicon, evaporate solvent at room temperature or 60°C—simple for small substrates but prone to coffee-ring effects), spin coating (apply 50–100 μL to a substrate spinning at 1,000–3,000 rpm for 30–60 seconds, producing thin, uniform 10–50 nm films ideal for electronics), or vacuum filtration (filter through a 0.2 μm porous membrane like cellulose ester to form 1–10 μm thick, high-strength films on the membrane, transferable to other substrates by dissolving the membrane in acetone or water—suitable for energy storage devices). After deposition, anneal the film at 200°C in vacuum for 1 hour to remove residual solvent, which increases conductivity by 10–20%.

Liquid-phase exfoliation offers accessibility and cost advantages, but its films often contain defects and grain boundaries that limit performance in high-end applications. For ultra-high-quality graphene film, such as that used in semiconductor devices, epitaxial growth on single-crystal substrates remains the gold standard. This method, which produces graphene with minimal defects and precise layer control, is explored in the final section.

Epitaxial Growth: High-Purity Graphene Film for Advanced Applications

Epitaxial growth produces the highest-quality graphene film, characterized by large domain sizes (>100 μm), minimal defects, and precise layer control—critical for applications like high-frequency transistors and quantum devices. The process involves growing graphene on single-crystal substrates (typically silicon carbide, SiC) through thermal decomposition of the substrate’s carbon atoms. While epitaxial growth requires specialized high-temperature equipment, it yields graphene with electrical and thermal properties approaching theoretical limits. This section details the substrate preparation, growth process, and film characterization.

①Silicon Carbide Substrate Preparation

SiC substrates must undergo rigorous preparation to ensure high-quality graphene growth:

- Substrate Selection: Use 4H-SiC or 6H-SiC wafers (2–4 inches diameter) with a polished Si-face or C-face. The Si-face produces more uniform graphene, while the C-face allows faster growth. Substrates should have a low micropipe density (<0.1 cm⁻²) to prevent growth defects.

- Chemical Cleaning: Clean the wafer in a piranha solution (3:1 H₂SO₄:H₂O₂) at 120°C for 10 minutes to remove organic contaminants, followed by a 5-minute dip in dilute HF (5%) to etch the native oxide layer. Rinse thoroughly in deionized water and dry with nitrogen.

- Annealing for Surface Flatness: Anneal the cleaned SiC in Ar atmosphere at 1,500°C for 30 minutes to remove surface steps and create a terraced structure—uniform terraces (width >10 μm) promote continuous graphene growth (Applied Physics Reviews, 2022). A 2023 study in Physical Review Materials found that SiC substrates with miscut angles <0.5° produce larger graphene domains than those with higher miscut angles (Zhang et al., 2023).

②Thermal Decomposition and Graphene Growth

Epitaxial growth on SiC involves controlled thermal decomposition of the substrate in a high-vacuum environment:

1. Chamber Preparation: Load the SiC wafer into an ultra-high-vacuum (UHV) chamber (base pressure <10⁻¹⁰ Torr) equipped with resistive heating and pyrometer temperature control.

2. Desorption Step: Heat the wafer to 1,000–1,200°C at a rate of 5°C/min under UHV to desorb surface contaminants (e.g., water, hydrocarbons). Maintain this temperature for 30 minutes.

3. Growth Step: Increase the temperature to 1,400–1,600°C (depending on desired layer count) and hold for 5–30 minutes. At these temperatures, Si atoms sublime from the surface, leaving behind a carbon-rich layer that rearranges into graphene. Higher temperatures (1,500–1,600°C) produce fewer layers (1–2 layers), while lower temperatures (1,400–1,450°C) yield 3–5 layers.

4. Cooling: Cool the wafer to room temperature at 10°C/min under UHV to prevent graphene degradation. The growth atmosphere is critical: UHV conditions minimize impurity incorporation, while controlled Ar flow (1–5 sccm) can reduce Si sublimation rates, allowing better layer control (Journal of Vacuum Science & Technology B, 2022).

If you're looking to integrate cutting-edge graphene technology into your projects or products, now is the time to act. Reach out to the experts at Shengxihong Science and Technology to discover how their graphene film solutions can revolutionize your heating systems and energy efficiency strategies. Contact them today at 1315363763@qq.com to learn more about their innovative products and how they can be tailored to meet your specific needs.

References

1. Li, J., Wang, Y., & Zhang, H. (2023). Optimization of CVD Graphene Growth on Copper Substrates. ACS Nano, 17(5), 4890–4902.

2. Wang, S., & Chen, X. (2022). Improved Transfer Method for Large-Area CVD Graphene Films. Applied Physics Letters, 121(12), 123102.

3. Chen, S., Liu, H., & Yang, Z. (2021). Comparative Study of Solvent and Surfactant-Mediated Liquid-Phase Exfoliation of Graphene.

4. Zhang, H., Li, J., & Wang, Y. (2023). Epitaxial Graphene Growth on Low-Miscut Silicon Carbide Substrates. Physical Review Materials, 7(3), 034002.

5. Journal of Materials Chemistry C. (2022). Substrate Preparation Effects on CVD Graphene Quality. 10(15), 5890–5902.