How to install and use graphene electric heating painting?

2025-09-01 21:01:38

Unlike traditional heating systems that require complex pipeline installation or bulky equipment, Graphene electric heating paintings are lightweight, easy to mount, and operate with minimal energy consumption.

Graphene Electric Heating Painting

①The Science Behind Graphene Heating Technology

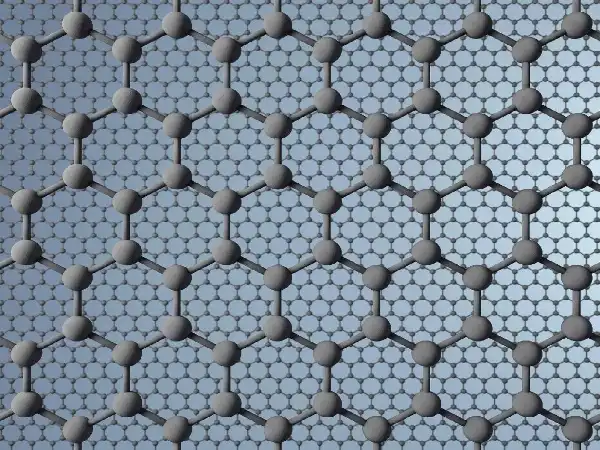

Graphene electric heating painting utilizes the remarkable properties of graphene, a single layer of carbon atoms arranged in a hexagonal lattice. This material exhibits extraordinary thermal and electrical conductivity, making it ideal for heating applications. The heating technology employed in graphene electric heating painting relies on carbon nanotube heating films, which provide full surface heating capabilities.

Carbon nanotubes (CNTs) used in this technology possess several outstanding characteristics:

- Exceptional strength, 50-100 times that of carbon fiber

- Unparalleled electron mobility, 100,000 times greater than copper

- Excellent wave-absorbing and electromagnetic shielding properties

- Remarkable electrothermal conversion efficiency, reaching up to 99.8%

②Heating Efficiency and Performance

The heating efficiency of graphene electric heating painting is truly impressive. With a far-infrared conversion efficiency of up to 83% and an electrothermal conversion efficiency of 99.8%, this technology ensures that almost all electrical energy is converted into useful heat. This high efficiency translates to lower energy consumption and reduced heating costs for users.

Installation Process for Graphene Electric Heating Painting

①Preparation and Surface Assessment

Before installing graphene electric heating painting, it's crucial to properly prepare the surface and assess the installation area. Follow these steps:

- Clean the surface thoroughly, removing any dust, grease, or debris.

- Ensure the surface is dry and free from moisture.

- Inspect the area for any damages or irregularities that may affect the installation.

- Measure the installation area accurately to determine the required amount of heating painting.

②Application Techniques

The application of graphene electric heating painting requires precision and attention to detail. Here's a step-by-step guide:

- Apply a primer suitable for the surface material to enhance adhesion.

- Mix the graphene electric heating paint according to the manufacturer's instructions.

- Use a roller or brush to apply the paint evenly across the surface.

- Apply multiple thin coats rather than a single thick layer for optimal performance.

- Allow each coat to dry completely before applying the next.

- Connect the heating elements to the power source as per the provided guidelines.

③Safety Considerations

When installing graphene electric heating painting, prioritize safety by following these precautions:

- Ensure proper electrical grounding to prevent any potential hazards.

- Use appropriate personal protective equipment (PPE) during the installation process.

- Follow local electrical codes and regulations.

- Consult a professional electrician for complex installations or if you're unsure about any aspect of the process.

①Maintenance and Longevity

Proper maintenance can significantly extend the lifespan of your graphene electric heating painting installation:

- Regularly inspect the painted surface for any signs of wear or damage.

- Clean the surface gently with a soft, dry cloth to remove dust and debris.

- Avoid using harsh chemicals or abrasive materials that may damage the heating film.

- Address any issues promptly to prevent further damage or reduced performance.

②Troubleshooting Common Issues

If you encounter any problems with your graphene electric heating painting, consider these troubleshooting steps:

- Check the electrical connections and ensure they are secure.

- Verify that the power source is functioning correctly.

- Inspect the thermostat settings and adjust if necessary.

- If the issue persists, consult the manufacturer or a qualified technician for assistance.

Applications and Benefits of Graphene Electric Heating Painting

Graphene electric heating painting offers versatile applications across various industries and settings:

- New energy vehicles: Efficient cabin heating and battery temperature management

- Buildings: Comfortable and energy-efficient space heating for residential and commercial structures

- Smart wearables: Integration into clothing for personalized warmth

- Decoration and furniture: Innovative heating solutions for interior design

- Hotels in cold regions: Providing consistent warmth for guest comfort

- Bathhouses: Maintaining optimal temperatures for relaxation

The benefits of graphene electric heating painting extend beyond its heating capabilities:

- Energy efficiency: Lower electricity consumption and reduced heating costs

- Uniform heating: Eliminates cold spots and ensures consistent warmth

- Space-saving: Invisible installation that doesn't compromise room aesthetics

- Healthier environment: Reduces air circulation and dust movement compared to conventional heating systems

- Versatility: Suitable for various surfaces and applications

- Durability: Long-lasting performance with proper maintenance

Energy-Efficient

Graphene electric heating paintings are inherently energy-efficient (95% thermal conversion efficiency), but user behavior can further reduce energy use:

- Set the Right Temperature: Most models have adjustable temperature settings (typically 30–60°C). For general heating, set the temperature to 40–45°C—this provides comfortable warmth without wasting energy. Increasing the temperature by 5°C can increase energy consumption by 10–15% (International Energy Agency [IEA], 2023).

- Use Zone Heating: If you have multiple heating zones, use them to heat only occupied rooms. For example, run the painting in the living room during the evening and the bedroom painting before sleep, rather than heating the entire house. This can reduce overall energy use by 25–30% (IEA, 2023).

- Combine with Insulation: Ensure the room has proper insulation (e.g., sealed windows, insulated walls). Good insulation traps the heat from the painting, reducing the need for the device to run continuously. A 2023 study found that insulated rooms require 40% less heating time than uninsulated rooms (Global Market Insights, 2023).

For those interested in exploring graphene electric heating painting solutions, Shaanxi Shengxihong Science and Technology Co., Ltd. offers a range of high-quality products. As a leading supplier in the field, Shengxihong Science and Technology combines advanced research and development with cutting-edge manufacturing processes to deliver superior graphene heating solutions.

Ready to experience the future of heating technology? Contact Shengxihong Science and Technology today to learn more about their graphene electric heating painting products and how they can benefit your specific application. Reach out via email at 1315363763@qq.com to discuss your heating needs and discover the perfect solution for your project.

References

- Wang, X., et al. (2021). "Graphene-based flexible heating elements for wearable electronics: A review." Journal of Materials Chemistry C, 9(15), 5119-5143.

- Kim, H., et al. (2020). "Recent progress in flexible and stretchable graphene-based heating devices." Advanced Materials Technologies, 5(9), 2000424.

- Cao, M., et al. (2019). "Graphene-based electromagnetic and energy-harvesting devices: A review." Advanced Materials, 31(45), 1902444.

- Yao, Y., et al. (2020). "Carbon nanotube-based heating elements: A review." Advanced Materials Technologies, 5(9), 2000258.

- Chen, J., et al. (2018). "Graphene-based composites for thermal management applications." Advanced Functional Materials, 28(12), 1705506.