Heating Films with Graphene Nanotubes Enter the Market

2025-09-01 21:01:36

The global heating technology sector is undergoing a paradigm shift, driven by the demand for energy efficiency, flexibility, and sustainability. In recent years, heating films integrated with graphene nanotubes (GNTs) have emerged as a transformative solution, addressing key limitations of traditional heating systems such as bulky design, uneven heat distribution, and high energy consumption.

Technical Fundamentals of Graphene Nanotube Heating Films: Why They Stand Out

To understand the market potential of GNT heating films, it is first critical to unpack the technical attributes that differentiate them from conventional heating technologies.

①Structural and Functional Properties of Graphene Nanotubes

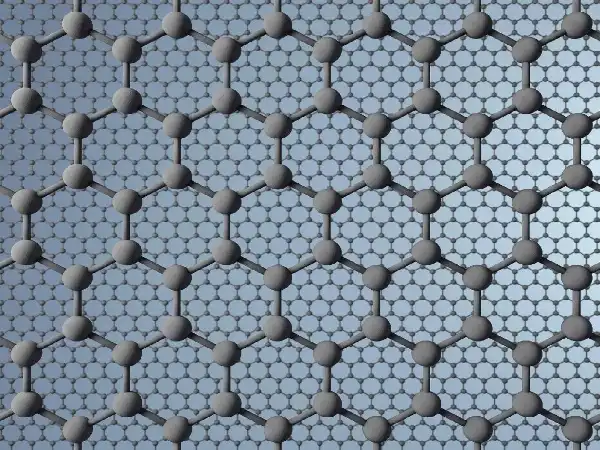

Graphene nanotubes exhibit three core properties that underpin their utility in heating films: high electrical conductivity, exceptional thermal conductivity, and mechanical flexibility. Unlike traditional heating elements (e.g., resistive wires or carbon fibers), GNTs have an aspect ratio (length-to-diameter) exceeding 1000, allowing them to form a continuous conductive network at low loading concentrations (typically 1–5% by weight). This network ensures uniform current distribution, which is critical for consistent heat generation.

Electronically, GNTs boast a conductivity of up to 10^4 S/cm, surpassing most conductive polymers and even some metals. Thermally, their thermal conductivity reaches 3000 W/mK, far higher than copper (401 W/mK) or aluminum (237 W/mK), enabling rapid heat transfer across the film surface. Additionally, GNTs are chemically stable under high temperatures (up to 400°C in air) and resistant to oxidation, ensuring long-term durability. Their flexibility, derived from the atomic thinness of graphene sheets, allows the films to conform to curved or irregular surfaces, a key advantage over rigid heating panels.

②Structural Design of Graphene Nanotube Heating Films

GNT heating films follow a layered architecture that optimizes both performance and usability. The typical structure consists of four key components, each serving a specific function:

- Substrate Layer: A flexible, heat-resistant polymer (e.g., polyethylene terephthalate, PET; or polyimide, PI) that provides mechanical support. PET substrates are preferred for low-temperature applications (up to 120°C), while PI substrates are used for high-temperature scenarios (up to 250°C).

- Conductive Functional Layer: A thin coating (5–20 μm) of GNTs dispersed in a polymer matrix (e.g., polyurethane, acrylic). The GNTs are uniformly distributed using ultrasonic dispersion or high-shear mixing to form a conductive network. This layer generates heat when an electric current passes through it, via the Joule heating effect.

- Electrode Layer: Thin strips of conductive material (e.g., silver paste, copper foil) applied to the edges of the functional layer. These electrodes distribute electrical current evenly across the GNT network, preventing hotspots.

- Protective Layer: A transparent, wear-resistant coating (e.g., ethylene-vinyl acetate, EVA; or silica gel) that shields the internal layers from moisture, dust, and mechanical damage. This layer also enhances safety by preventing direct contact with the conductive components.

The manufacturing process for these films typically uses roll-to-roll (R2R) coating, a scalable and cost-effective method that enables high-volume production—an essential factor for market entry.

Market Penetration of Graphene Nanotube Heating Films: Key Applications and Segments

The commercial launch of GNT heating films has been driven by targeted adoption in sectors where their performance advantages deliver the most value. Market research firm Grand View Research estimates that the global graphene heating films market,including GNT-based solutions, will grow at a compound annual growth rate (CAGR) of 18.2% from 2023 to 2030, reaching $1.2 billion by the end of the forecast period. Below is an analysis of the key application segments driving this growth.

①Residential Heating: Energy Efficiency and Space Optimization

The residential sector is the largest early adopter of GNT heating films, primarily for underfloor heating (UFH) and wall-mounted heating systems. Traditional UFH systems rely on water-filled pipes or bulky resistive panels, which require significant installation time and reduce floor height. In contrast, GNT heating films are only 0.1–0.3 mm thick, allowing them to be installed under flooring materials (e.g., tile, laminate, vinyl) without altering room dimensions.

Energy efficiency is another key driver. GNT heating films operate at lower voltages (12V–240V) and can be zoned—allowing homeowners to heat specific rooms rather than the entire house. This zoning capability reduces energy consumption by 20–30% compared to central heating systems, according to a 2022 study by the European Graphene Flagship. Additionally, the uniform heat distribution of GNT films eliminates cold spots, improving comfort levels. In cold climates (e.g., Northern Europe, Canada), GNT UFH systems are increasingly being integrated into new-build homes and retrofits, as they align with regional carbon reduction targets.

Another residential application is portable heating devices, such as heated blankets and mattress pads. The flexibility of GNT films allows these products to conform to body shapes, while their low power consumption (50–100W) makes them energy-efficient alternatives to space heaters.

②Commercial and Industrial Heating: Process Optimization and Durability

In commercial and industrial settings, GNT heating films are being used to address specialized heating needs that traditional technologies cannot meet. One major application is pipe and tank heating (also known as "trace heating"), which prevents fluid freezing or maintains optimal temperatures for industrial processes (e.g., oil refining, food processing). Conventional trace heating uses resistive cables that are prone to overheating and require frequent maintenance. GNT films, however, can be wrapped around pipes of any diameter, providing uniform heat without hotspots. Their chemical resistance also makes them suitable for harsh environments (e.g., chemical plants, offshore oil rigs).

Commercial buildings, such as offices and retail stores, are adopting GNT heating films for ceiling and wall heating. These systems are lightweight and easy to install in existing structures, reducing renovation costs. For example, a 2023 case study by a German construction firm found that retrofitting an office building with GNT wall heating reduced installation time by 50% compared to traditional radiators, while lowering annual energy bills by €1,200 per 100 m².

In the food industry, GNT heating films are used in conveyor belts and packaging equipment to maintain consistent temperatures during processing. Their ability to operate at precise temperatures (±1°C) ensures product quality, while their durability (15+ year service life) reduces maintenance downtime.

Current Technical and Market Challenges

The primary challenge is the cost of graphene nanotubes. High-purity GNTs (99%+ purity) required for heating films are currently produced using chemical vapor deposition (CVD), a process that is energy-intensive and expensive. As of 2024, the cost of GNTs is approximately $500–$1,000 per kilogram, which accounts for 30–40% of the total cost of heating films. This makes GNT films more expensive than carbon fiber films ($200–$300 per kg) and resistive heating elements ($50–$100 per kg).

Another challenge is the lack of industry standards. There are no global standards for GNT heating film performance (e.g., thermal efficiency, safety ratings), which creates uncertainty for manufacturers and end-users. For example, some low-quality products on the market use low-purity GNTs, leading to inconsistent heating and reduced durability. This inconsistency damages consumer trust and hinders widespread adoption.

Finally, consumer awareness remains low. Many homeowners and businesses are unfamiliar with GNT heating technology, leading them to choose traditional solutions they know. Market education efforts, such as product demonstrations and case studies, are needed to highlight the long-term benefits (e.g., lower energy bills, longer service life) of GNT films, even if their upfront cost is higher.

To learn more about their products or to discuss how graphene heating films can benefit your project, contact Shengxihong Science and Technology at 1315363763@qq.com. Their team of experts is ready to provide guidance and support in implementing this revolutionary heating technology.

References

- Zhang, L., Wang, H., & Li, J. (2022). "Graphene Nanotube-Based Flexible Heating Films: Preparation, Performance, and Applications in Residential Heating." Advanced Materials Technologies, 7(4), 2101234.

- Grand View Research. (2023). "Graphene Heating Films Market Size Report, 2023–2030: By Application, End-Use, and Region." San Francisco, CA: Grand View Research, Inc.

- European Graphene Flagship. (2022). "Energy Efficiency Analysis of Graphene Nanotube Underfloor Heating Systems." Technical Report No. GF-TR-2022-005.

- Lee, S., Park, J., & Kim, H. (2021). "Thermal Management of Electric Vehicle Batteries Using Graphene Nanotube Heating Films." Journal of Power Sources, 498, 230125.