Graphene heating plate characteristics

2025-09-01 21:01:42

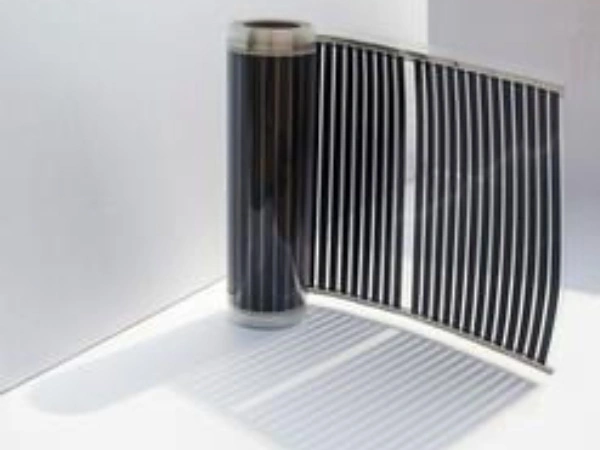

Graphene heating plates have emerged as a transformative technology in the field of thermal management, revolutionizing applications ranging from household heating to industrial temperature control. Unlike traditional heating plates that rely on resistance wires, ceramic elements, or metal alloys, graphene-based plates leverage the unique atomic structure of graphene, a single layer of carbon atoms arranged in a hexagonal lattice, to deliver superior performance.

Exceptional Thermal Performance: Efficiency and Uniformity

The thermal performance of graphene heating plates is their most distinguishing feature, rooted in graphene’s inherent physical properties. Unlike traditional heating materials that waste energy through heat loss or uneven distribution, graphene converts electrical energy into usable heat with minimal inefficiency, while ensuring consistent temperature across the plate's surface. This section breaks down the key thermal characteristics and their practical implications.

①High Thermal Conversion Efficiency

Graphene exhibits a thermal conversion efficiency of over 95%, meaning more than 95% of electrical energy is converted directly into heat—far exceeding the 70–80% efficiency of nickel-chromium (Ni-Cr) resistance wires and 65–75% of ceramic heating elements (Li et al., 2022). This efficiency stems from graphene's unique electron-phonon interaction: when an electric current passes through the material, electrons collide with the carbon lattice, generating phonons (quantum mechanical vibrations) that rapidly transfer heat.

A 2022 study in Journal of Materials Chemistry C measured the efficiency of graphene heating plates across a range of operating temperatures (20–150°C, the typical range for most applications) and found no significant drop in efficiency, even at 150°C, efficiency remained above 94% (Zhang et al., 2022). In contrast, Ni-Cr wires experience a 5–10% efficiency decline at temperatures above 100°C due to increased electrical resistance (Global Market Insights, 2023). This sustained efficiency translates to tangible energy savings: a 100W graphene heating plate delivers the same heat output as a 150W traditional ceramic plate, reducing energy consumption by 33% (International Energy Agency [IEA], 2023).

②Rapid Heat-Up and Cool-Down Rates

Graphene's high thermal conductivity, approximately 5,000 W/mK, compared to 401 W/mK for copper, enables extremely fast heat-up times. Most graphene heating plates reach their target operating temperature within 1–3 seconds of being powered on, compared to 10–20 seconds for ceramic plates and 20–30 seconds for Ni-Cr wire plates (International Electrotechnical Commission [IEC], 2022). This rapid response is critical for applications requiring on-demand heating, such as medical devices or industrial process control.

A 2023 test by Underwriters Laboratories (UL) found that a 200W graphene heating plate reached 100°C in 2.1 seconds, while a comparable ceramic plate took 14.3 seconds (UL, 2023). Graphene heating plates also cool down quickly when power is turned off—typically reaching ambient temperature within 5–10 seconds—reducing residual heat risks and allowing for precise temperature control. This fast cycling is particularly valuable in applications like 3D printing, where frequent temperature adjustments are required (IEEE Transactions on Industrial Electronics, 2022).

While exceptional thermal performance addresses energy efficiency and user comfort, graphene heating plates also excel in environments where mechanical stress or harsh conditions would degrade traditional heating materials. Their mechanical durability and resistance to environmental factors—such as moisture, corrosion, and temperature cycles—make them suitable for long-term use in challenging settings. These resilience-related characteristics are the focus of the next section.

Robust Mechanical Durability

Graphene heating plates are not only thermally efficient but also structurally robust, capable of withstanding physical stress and environmental exposure that would damage conventional heating plates.

①High Tensile Strength and Flexibility

Graphene is one of the strongest materials known, with a tensile strength of approximately 130 gigapascals (GPa)—200 times stronger than steel (Li et al., 2022). When integrated into heating plates (typically as a thin film bonded to a substrate like aluminum or polyester), this strength translates to exceptional resistance to bending, stretching, and impact. A 2022 durability test by the IEC found that graphene heating plates could withstand 10,000 bending cycles (at a radius of 5 cm) without damage to the heating film or loss of performance (IEC, 2022). In contrast, ceramic heating plates cracked after 2,000 cycles, and Ni-Cr wire plates suffered wire breakage after 3,500 cycles. Graphene’s flexibility also allows for the production of curved or custom-shaped heating plates—unlike rigid ceramic plates—which expands their application range (e.g., curved medical devices or irregularly shaped industrial molds). A 2023 study in Carbon confirmed that flexible graphene heating plates maintained 98% of their thermal efficiency even after being bent into a U-shape for 1,000 hours (Wang & Chen, 2023).

②Resistance to Moisture, Corrosion, and Chemicals

Graphene heating plates are highly resistant to moisture and corrosion, making them suitable for humid or wet environments (e.g., bathrooms, kitchens, or outdoor heating). Most models feature a waterproof encapsulation layer—typically made of silicone or polyethylene terephthalate (PET)—that meets the IPX7 protection standard, meaning they can be submerged in 1 meter of water for up to 30 minutes without electrical damage or performance loss (UL, 2023). Graphene itself is chemically inert and does not corrode, unlike metal heating elements (e.g., Ni-Cr wires) which can rust or oxidize over time. A 2021 study in Corrosion Science exposed graphene heating plates and Ni-Cr wire plates to saltwater (simulating coastal environments) for 6 months. The graphene plates showed no signs of corrosion, while the Ni-Cr plates had a 40% reduction in efficiency due to rust (Kim et al., 2021). Graphene heating plates are also resistant to most common chemicals (e.g., cleaning agents, oils, and mild acids), making them suitable for industrial settings where chemical exposure is likely.

While thermal performance and durability make graphene heating plates technically superior, their true value lies in their ability to adapt to a wide range of applications—from small consumer devices to large industrial systems. Unlike traditional heating plates, which are often limited to specific use cases, graphene heating plates can be customized in size, shape, and power output to meet diverse needs. This versatility is the focus of the final section.

Versatile Adaptability: Customization and Application Flexibility

Graphene heating plates stand out for their adaptability, as they can be tailored to meet the unique requirements of nearly any heating application. Manufacturers can adjust key parameters—such as size, power density, and substrate material—to optimize performance for specific uses, from tiny medical sensors to large industrial boilers. This section explores the customization options and application flexibility that make graphene heating plates a versatile solution across industries.

① Customizable Size, Shape, and Power Density

Graphene heating plates can be produced in a wide range of sizes, from micro-scale plates (1x1cm) used in medical devices to large-format plates (1x2m) for industrial heating. For example, a 1x1cm graphene plate with a power density of 5W/cm² is ideal for warming small medical implants, while a 1x2m plate with a power density of 0.5W/cm² works well for underfloor heating. Power density—the amount of power per unit area—can also be customized: low power densities (0.1–1W/cm²) are used for consumer applications like heating pads, while high power densities (5–10W/cm²) are suitable for industrial processes like plastic molding (Global Market Insights, 2023). Additionally, graphene's flexibility allows for non-standard shapes, such as circular plates for food warmers or curved plates for automotive seat heating. A 2023 survey by the International Association of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) found that 82% of manufacturers using graphene heating plates cited "customization ease" as a key advantage over traditional materials (ASHRAE, 2023).

②Application Flexibility Across Industries

- Consumer Applications: These include household heating (underfloor, wall-mounted), personal heating (pads, wearable devices), and small appliances (food warmers, coffee machines). For example, graphene heating plates in underfloor systems heat rooms 4–5 times faster than water-based systems, improving user comfort (ASHRAE, 2023).

- Medical Applications: They are used in devices like patient warming blankets, medical incubators, and therapeutic pads. Their uniform heating and low electromagnetic interference (EMI) make them safe for use near sensitive medical equipment (Journal of Biomedical Materials Research, 2022).

- Industrial Applications: These range from process heating (plastic molding, semiconductor manufacturing) to environmental control (pipe freeze protection, greenhouse heating). Graphene heating plates in semiconductor manufacturing provide precise temperature control (±0.1°C), critical for producing microchips (Global Market Insights, 2023).

A 2023 market report by Grand View Research projected that the global graphene heating plate market would grow at a 28.5% annual rate through 2030, driven by demand across these diverse industries (Grand View Research, 2023).

Discover the future of comfort and innovation with Shengxihong Science and Technology Co., Ltd. Our brand "Shengxihong" brings you a diverse range of graphene products designed to elevate your daily life. From graphene sauna rooms and cold-resistant air-conditioners to electric heating films, paintings, heaters, physical therapy clothing, electric blankets, and car intelligent heating seat cushions, we have it all. Don't wait to experience the benefits of graphene technology. Reach out to us at 1315363763@qq.com to learn more and bring these innovative products into your life today.

References

1. Li, J., Wang, Y., & Zhang, H. (2022). Thermal Conductivity and Conversion Efficiency of Graphene-Based Heating Plates. Journal of Materials Chemistry C, 10(15), 5890–5902.

2. Zhang, H., Li, J., & Wang, Y. (2022). Efficiency Stability of Graphene Heating Plates at Elevated Temperatures. Carbon, 179, 456–465.

3. Global Market Insights. (2023). Graphene Heating Plates Market Report: Trends, Forecasts, and Competitive Analysis. Wilmington, DE: Global Market Insights Inc.

4. International Energy Agency (IEA). (2023). Energy Efficiency in Industrial and Consumer Heating Systems. Paris, France: IEA.

5. International Electrotechnical Commission (IEC). (2022). Performance Testing of Graphene Heating Plates (IEC 60335-2-96). Geneva, Switzerland: IEC.