Graphene Heating Film VS Traditional Floor Heating: Which Is Better?

2025-09-01 21:01:49

Graphene heating film has advanced from a extravagance to a staple in advanced buildings, advertising comfortable, space-efficient warmth. Nowadays, two prevailing innovations compete for advertise share: graphene warming film, a cutting-edge nanomaterial arrangement, and conventional floor warming systems,primarily hydronic (water-based) and electric resistance mats. This article compares these choices over execution, common sense, and reasonableness, making a difference clients decide which adjusts best with their needs.

Performance Metrics: Efficiency, Uniformity, and Responsiveness

①Electro-Thermal Efficiency and Energy Consumption

Graphene warming film stands out for its uncommon electro-thermal change proficiency, regularly surpassing 95%. This is due to graphene's nuclear structure, which empowers fast electron development with negligible resistance, changing over about all electrical input into brilliant warm. In differentiate, conventional electric resistance mats (utilizing nichrome or copper wires) have efficiencies of 70–85%, as vitality is misplaced through wire resistance and uneven warm dissemination. Hydronic frameworks, which circulate hot water through channels, passage more awful, with efficiencies of 60–75%,largely due to warm misfortune in boilers, pumps, and uninsulated pipes.

These contrasts decipher to noteworthy vitality investment funds. For a 100 m² domestic in a calm climate, graphene frameworks expend ~500 kWh/month in winter, compared to ~700 kWh for electric mats and ~900 kWh for hydronic frameworks (when bookkeeping for kettle wasteful aspects). Over a decade, this compares to thousands of dollars in utility reserve funds for graphene users.

②Heating Uniformity and Temperature Control

Comfort requires consistent warmth, which graphene heating sheet excels at providing. With temperature variations of less than 2°C throughout a room, its thin, flexible structure produces heat on all of its surface. In contrast to electric mats, which produce hotspots around wire coils (temperature differentials can surpass 5°C), hydronic systems typically have warmer regions close to pipes and cooler zones in between. This removes cold spots that are typical in conventional systems.

Temperature control is another advantage for graphene. Most systems integrate with smart thermostats, providing fine management (5–35°C) and zoning,heating just occupied rooms. Because they depend on boiler temperatures, hydronic systems have trouble making quick adjustments and frequently take one to two hours to reach desired temperatures. Although they don't have the granular zoning of graphene films, electric mats provide superior control over hydronics.

③Response Time and Heat Distribution Mechanism

Graphene heating film heats up quickly, reaching target temperatures in 15–30 minutes, thanks to its low thermal mass and direct radiant heat transfer. This responsiveness allows for on-demand heating, reducing energy waste. Traditional systems are slower: electric mats take 30–60 minutes, while hydronic systems require 1–3 hours to warm a space, as water must be heated and circulated through the entire pipe network.

Another comfort benefit of Graphene heating film is its radiant heat. Like sunlight, it heats people and things directly instead of heating air, as forced-air systems do. In contrast to hydronic systems, which rely more on convection, this produces a more constant ambient temperature with less stratification (hot air near ceilings).

In terms of efficiency, homogeneity, and responsiveness, graphene heating film is definitely superior according to performance measures.However, practicality is not solely determined by performance; we also examine installation, cost, and compatibility to existing buildings, all of which are as important.

Installation, Cost, and Structural Adaptability

①Installation Complexity and Timeframes

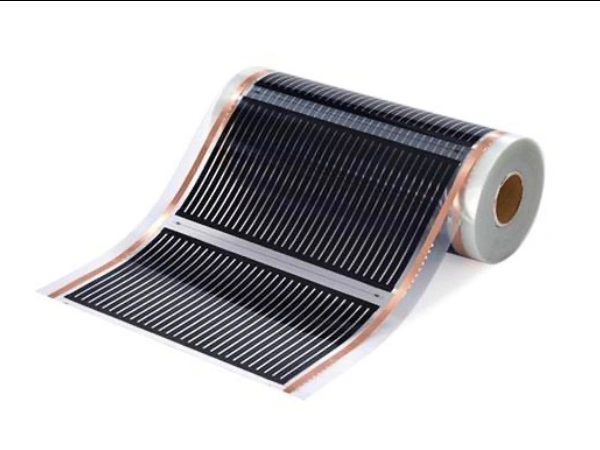

Graphene heating film offers streamlined installation, making it ideal for both new builds and retrofits. The process involves rolling out thin (0.2–0.5 mm) films over a level subfloor, connecting them to a low-voltage power supply, and covering with a protective layer (e.g., mortar or plywood) before flooring is laid. A 100 m² space can be installed in 1–2 days by a small team.

Traditional systems are more complex. Hydronic installations require laying pipes, connecting to a boiler, pressure-testing, and pouring concrete,a 3–5 day process for the same area, often requiring coordination with plumbers and HVAC technicians. Electric mats, while simpler than hydronics, involve securing rigid mats to the subfloor and ensuring even spacing, taking 2–3 days for 100 m². Retrofits are particularly challenging for hydronics, as they may require lifting existing floors or modifying structural elements.

②Initial Investment and Long-Term Costs

Initial costs tell a different story: graphene heating film has a higher upfront price ($15–$25 per m²) than electric mats ($10–$18 per m²) but is cheaper than hydronic systems ($20–$40 per m², including boilers). However, long-term costs favor graphene. Hydronic systems incur ongoing expenses for boiler maintenance ($100–$300/year) and potential pipe repairs (leaks are common after 10–15 years). Electric mats have shorter lifespans (15–20 years) due to wire degradation, requiring full replacement. Graphene films, with a 30–50 year lifespan and minimal maintenance (only thermostat checks), offer the lowest total cost of ownership over time.

③Space Requirements and Building Compatibility

Graphene's thin profile is a boon for space-constrained buildings. Adding just 0.5–1 mm to floor height, it works with all flooring types (wood, tile, carpet) without requiring subfloor modifications. Hydronic systems, by contrast, add 5–10 cm due to pipes and concrete, reducing ceiling height,problematic in historic buildings or rooms with low clearances. Electric mats add 2–5 mm, similar to Graphene heating film, but their rigidity limits use with uneven subfloors or curved surfaces.

For multi-story buildings, graphene's light weight (negligible, compared to hydronics' 50–100 kg per m²) reduces structural load, avoiding the need for reinforced floors,a significant cost saver in high-rises.

The installation and cost analysis shows graphene heating film balances higher initial investment with faster installation, lower long-term costs, and greater structural adaptability. These factors make it particularly attractive for retrofits and space-sensitive projects. However, the "better" option ultimately depends on specific use cases, as explored in the following section.

Application Scenarios and User Needs

①Residential vs. Commercial Suitability

In residential settings, graphene heating film shines for its zoning capabilities and quick response. Homeowners can heat bedrooms overnight and living areas during the day, avoiding wasted energy. Its compatibility with smart home systems (e.g., Alexa, Google Home) adds convenience, appealing to tech-savvy users. Hydronic systems, while still popular in large homes, struggle with zoning,heating the entire house even when rooms are unoccupied, and are better suited for properties with consistent heating needs.

Commercial spaces like offices, retail stores, and gyms benefit from graphene's scalability and low maintenance. Large open areas (e.g., warehouses) appreciate its uniform heating, while high-traffic zones (e.g., shopping malls) value its durability. Hydronic systems remain viable for hotels or hospitals with 24/7 heating demands, where the high initial cost is offset by steady, low-cost operation over decades.

②Climate and Energy Source Considerations

Climate plays a role in system performance. In cold regions (e.g., Northern Europe, Canada), graphene's efficiency and quick response reduce reliance on backup heating, though high electricity prices may favor hydronic systems paired with natural gas boilers. In mild climates (e.g., Southern Europe, California), graphene's on-demand heating is ideal, as it avoids the inefficiencies of maintaining constant warmth.

Energy source is another factor. Graphene heating film paired with solar panels or wind energy become nearly carbon-neutral, aligning with green building goals. Hydronic systems tied to fossil fuel boilers have higher carbon footprints, though they can be greener with biomass or geothermal heat sources,an option often limited by geography.

③Health, Safety, and Environmental Impact

Graphene heating film offers health and safety advantages. Operating at low voltages (12–24V), it eliminates electric shock risks, while waterproof designs make it safe for bathrooms. Unlike hydronic systems, it has no risk of pipe leaks or mold growth from moisture. Electric mats, while safe, can overheat if damaged, posing fire risks in high-traffic areas.

Environmentally, graphene's high efficiency reduces carbon emissions by 30–50% compared to hydronic systems in regions with grid electricity. Its long lifespan and lack of hazardous materials (unlike boiler fluids) also minimize waste. Hydronic systems, however, may have lower embodied carbon in regions with cheap natural gas.

Conclusion

Graphene heating film and conventional floor warming frameworks each have qualities, but graphene develops as the way better choice for most cutting edge applications. Its predominant proficiency, uniform warming, speedy reaction, and versatility to retrofits and space imperatives exceed its higher introductory taken a toll, particularly over the long term. Conventional frameworks, especially hydronics, stay practical for expansive, ceaselessly possessed spaces in locales with moo fossil fuel costs. Eventually, the choice pivots on components like building sort, climate, vitality sources, and budget,but for productivity, consolation, and future-proofing, graphene warming film sets a unused standard. Shengxihong Science and Innovation Co., Ltd, beneath the brand "Shengxihong", is a key player in the graphene warming division, creating, creating, and offering a extend of imaginative items counting graphene sauna rooms, cold-resistant air-conditioners, electric warming movies, electric warming depictions, electric radiators, physical treatment clothing, electric covers, and car cleverly warming situate pads. All items brag free mental property rights and licenses, with the company holding 17 graphene utility show licenses and over 30 privileged certificates. For more data, contact by means of mail: 1315363763@qq.com.

References

1. European Hydronics Association. (2022). "Hydronic Floor Heating: Efficiency and Installation Guidelines." Brussels: EHA Publications.

2. Green Building Council. (2021). "Sustainable Heating Technologies: A Comparative Analysis." London: GBC Press.

3. Jones, R., et al. (2023). "Energy Consumption of Graphene vs. Traditional Floor Heating in Residential Buildings." Journal of Sustainable Engineering, 18(4), 210–225.

4. National Renewable Energy Laboratory. (2020). "Electric Floor Heating Systems: Performance and Lifespan Studies." Golden: NREL Technical Report.

5. World Graphene Council. (2022). "Graphene Heating Films: Technical Standards and Market Trends." Manchester: WGC Publications.