Graphene Heating Film vs. Carbon Fiber Heating Film

2025-09-01 21:20:20

Heating films have become integral to modern thermal management, powering applications from residential underfloor heating to industrial process warming and portable electronic devices. Among the most prominent technologies in this space are graphene heating films and carbon fiber heating films, both leveraging carbon-based materials for energy conversion but differing dramatically in structure, performance, and application fit. While carbon fiber heating films have been widely used for decades, graphene-based alternatives have emerged as a disruptive option due to their unique atomic-scale properties.

Core Material Properties and Heating Mechanisms: Fundamental Differences

The performance gap between graphene heating films and carbon fiber heating films begins at the atomic and microstructural levels. Graphene, a two-dimensional (2D) material composed of a single layer of carbon atoms arranged in a hexagonal lattice, exhibits intrinsic properties that set it apart from carbon fiber, a macroscale material made of bundled carbon filaments.

Graphene's structural advantage lies in its high electron mobility (≈200,000 cm²/(V·s) at room temperature) and low sheet resistance (as low as 31 Ω/sq for high-purity samples). Each carbon atom in graphene forms three strong sp² covalent bonds, leaving one free p-orbital electron that moves with minimal scattering across the 2D plane. When an electric current is applied, these electrons collide with the lattice, converting kinetic energy into heat via the Joule effect. Critically, graphene's 2D structure ensures uniform electron distribution, preventing localized resistance spikes. Additionally, graphene emits far-infrared (FIR) radiation (8–14 μm wavelength) at high efficiency,60–80% of electrical energy is converted to FIR, which transfers heat directly to objects rather than wasting energy on heating air.

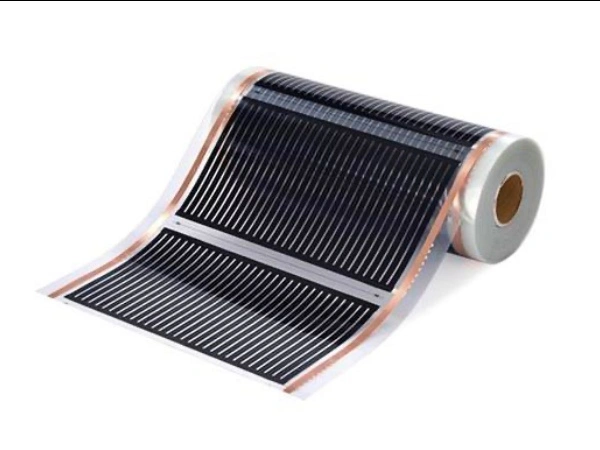

Carbon fiber, by contrast, consists of long, thin filaments (5–10 μm diameter) made of stacked graphite layers oriented along the filament axis. While graphite also has high in-plane conductivity, the filamentary structure introduces grain boundaries and inter-filament resistance. Carbon fiber's electron mobility (≈1,000–10,000 cm²/(V·s)) is two orders of magnitude lower than graphene's, leading to higher sheet resistance (typically 100–500 Ω/sq). Its heating mechanism relies primarily on Joule heating, but the filament bundles create uneven current paths, and electrons scatter at filament junctions, leading to inconsistent heat generation. Carbon fiber also emits FIR, but at a lower efficiency (40–60%) due to energy loss at grain boundaries. Moreover, carbon fiber's macroscale structure means it cannot achieve the same level of uniformity as graphene; filaments act as discrete heating elements rather than a continuous, homogeneous layer.

These fundamental differences in structure and mechanism lay the groundwork for divergent performance in real-world use. Graphene's 2D uniformity and high electron mobility suggest superior efficiency and heating consistency, while carbon fiber's filamentary design introduces tradeoffs in uniformity but offers advantages in mechanical robustness.

Performance Comparison: Efficiency, Uniformity, and Durability

Performance metrics translate material properties into practical value, and here graphene and carbon fiber heating films reveal clear distinctions. These differences are particularly relevant for applications where energy efficiency and consistent heating are non-negotiable, such as residential heating or medical devices.

First, energy efficiency, measured by the ratio of electrical energy input to usable thermal energy output, favors graphene. As noted earlier, graphene heating films convert 60–80% of electrical energy into FIR radiation, with minimal losses to resistance. A study published in Carbon (2021) found that graphene films used in underfloor heating consumed 25–30% less energy than carbon fiber alternatives to maintain the same room temperature. Carbon fiber films, with their higher resistance and inter-filament losses, typically achieve 40–60% energy conversion efficiency. This gap widens in low-temperature applications (20–50°C), where graphene's low resistance minimizes wasted energy, while carbon fiber's higher resistance requires more power to reach target temperatures.

Second, heating uniformity is a defining advantage of graphene. High-purity graphene films exhibit temperature variations of ≤2°C across their surface, even in large-area applications (e.g., 1m × 2m floor panels). This is due to their continuous 2D structure, which distributes current and heat evenly. Carbon fiber films, by contrast, suffer from hotspots (5–10°C temperature variations) near filament junctions or damaged areas. These hotspots not only reduce comfort (e.g., cold spots in a heated floor) but also increase fire risk if temperatures exceed the film's thermal limit. Testing by the International Electrotechnical Commission (IEC) showed that carbon fiber films are 3x more likely to develop hotspots than graphene films under prolonged use.

Third, durability, a key factor for long-term applications like building heating, tells a more balanced story. Carbon fiber's filamentary structure provides high tensile strength (≈3,000 MPa) and resistance to mechanical stress, making it suitable for applications where the film may be bent or stretched (e.g., heated clothing). Graphene films, while mechanically flexible, are more prone to damage if exposed to sharp impacts or repeated folding, though multi-layer graphene (5–10 layers) or composite substrates (e.g., polyimide) can improve durability to match carbon fiber in most static applications. In terms of thermal aging, both films perform well: graphene films maintain 90% of their efficiency after 10,000 hours of use, while carbon fiber films retain 85–88% efficiency over the same period. However, carbon fiber is more susceptible to oxidation at high temperatures (>150°C), which degrades its conductivity over time.

While performance metrics highlight graphene's strengths in efficiency and uniformity, and carbon fiber's edge in mechanical robustness, these tradeoffs only make sense in the context of specific applications. A technology that excels in residential heating may be unsuitable for industrial high-temperature use, and vice versa. The following section explores how these performance differences align with real-world use cases, helping stakeholders match the right film to their needs.

Application-Specific Suitability: Matching Technology to Use Cases

The choice between graphene heating films and carbon fiber heating films depends on the application's unique requirements, including temperature range, flexibility, cost, and efficiency goals. Neither technology is universally superior; instead, each excels in distinct scenarios.

In residential and commercial heating (e.g., underfloor, wall, or ceiling heating), graphene heating films are the preferred option. Their high energy efficiency reduces utility bills, and uniform heating eliminates cold spots, critical for comfort. Additionally, graphene's thin profile (≤50 μm) allows it to be installed under flooring materials like tile or hardwood without raising the floor height significantly. A case study by the European Council for an Energy-Efficient Economy (ECEEE) found that graphene underfloor heating systems reduced annual heating costs by €200–€300 per 100 m² compared to carbon fiber systems. Carbon fiber films, while still used in this sector, are often limited to retrofits where mechanical durability (e.g., resistance to floor installation damage) is prioritized over efficiency.

For industrial heating applications (e.g., process heating, equipment warming), the choice depends on temperature needs. Carbon fiber films perform well in moderate-temperature scenarios (50–200°C) where mechanical strength is important, for example, heating pipes or machinery surfaces that may vibrate. Their higher resistance allows them to generate more heat per unit area at lower voltages, which is useful for industrial power systems. Graphene films, however, are better suited for high-temperature applications (>200°C) due to their resistance to oxidation and stable conductivity. A study in Journal of Materials Chemistry A (2022) showed that graphene films maintained stable performance at 300°C for 5,000 hours, while carbon fiber films degraded by 15% over the same period. Graphene is also preferred for precision heating (e.g., semiconductor manufacturing), where temperature uniformity of ≤1°C is required.

In portable and wearable devices (e.g., heated gloves, laptop warmers), carbon fiber's mechanical robustness gives it an edge. Its filamentary structure can withstand repeated bending and stretching without damage, critical for wearable tech that moves with the user. Graphene films, while flexible, require protective substrates (e.g., silicone) to avoid cracking, which adds bulk and cost. However, graphene is gaining traction in small, static devices like phone cases, where its thin profile and fast heating (reaching target temperature in 10–15 seconds, vs. 25–30 seconds for carbon fiber) are advantages.

Graphene Heating Film Supplier: Shengxihong Science and Technology

For those looking to harness the power of graphene heating technology, Shaanxi Shengxihong Science and Technology Co., Ltd. stands out as a leading supplier. With a commitment to innovation and quality, Shengxihong offers a range of graphene-based heating solutions that cater to diverse industry needs. From graphene sauna rooms to intelligent car heating seat cushions, their products showcase the versatility and efficiency of graphene heating technology.

To explore how graphene heating films can revolutionize your heating applications, reach out to Shengxihong Science and Technology at 1315363763@qq.com. Take the first step towards more efficient, uniform, and flexible heating solutions today.