Graphene Floor Heating VS Ordinary Underfloor Heating

2025-09-01 21:01:43

As energy-efficient and sustainable technologies continue to evolve, graphene floor heating stands out as an innovative replacement for traditional underfloor heating. For households and businesses aiming to cut costs and reduce environmental impact, it's important to compare these two systems. In this article, we break down the differences in materials, functionality, heating performance, and energy usage between graphene-based and conventional floor heating

Technical Fundamentals and Operational Mechanisms

①Core Material Composition

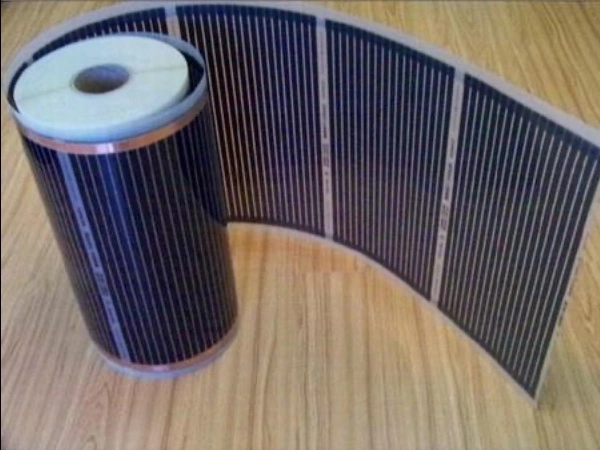

Graphene floor heating systems are characterized by their utilization of graphene heating films as the core component. These movies are made of thin, flexible sheets of graphene, a carbon-based nanomaterial that is known for being very good at conducting heat and electricity. Graphene's unique atomic structure, which is made up of a single sheet of carbon atoms organized in a hexagonal lattice, gives it better heat transfer properties. This choice of material ensures that the heating elements can make and spread heat very well.

In contrast, ordinary underfloor heating systems exhibit more diverse core material compositions. Water-based underfloor heating, the most common type of ordinary system, relies on a network of pipes, typically made of cross-linked polyethylene (PEX) or polybutylene (PB), which carry heated water. Traditional electric underfloor heating systems, another variant of ordinary systems, use heating cables composed of copper or nickel-chromium alloys, or carbon fiber mats, which have relatively lower thermal conductivity compared to graphene.

②Energy Conversion and Heat Distribution Principles

The operational principle of graphene floor heating involves the direct conversion of electrical energy into thermal energy through the graphene material. When an electric current passes through the graphene heating film, the material rapidly generates heat due to its high electrical conductivity. This heat is then radiated evenly upward through the floor surface, without the need for intermediate heat transfer media such as water or air. The excellent thermal conductivity of graphene ensures that heat spreads quickly across the entire floor area, resulting in a uniform temperature distribution.

Shaanxi Shengxihong Science and Technology Co., Ltd, a leading innovator in graphene heating solutions, has developed a proprietary graphene heating film that forms the core of their floor heating systems. This film incorporates carbon nanotubes (CNTs), which further enhance the material's performance. CNTs exhibit extraordinary strength,50 to 100 times that of carbon fiber, and possess electron mobility 100,000 times greater than copper. These properties contribute to the system's excellent wave-absorbing and electromagnetic shielding capabilities.

For ordinary underfloor heating systems, the energy conversion and heat distribution processes differ significantly. Water-based systems operate by heating water in a boiler, which is then pumped through the network of pipes under the floor. Heat is transferred from the hot water to the floor surface through conduction, and then radiated into the room. This process involves multiple stages of heat transfer, leading to inherent energy losses. Traditional electric underfloor heating systems convert electrical energy into heat through the resistance of the heating cables or carbon fiber mats. However, their lower thermal conductivity means that heat generation and distribution are less efficient, often resulting in uneven temperature zones across the floor.

Heating Efficiency & Speed

①Graphene's Rapid Response and Uniform Heat Distribution

One of the most significant advantages of graphene floor heating is its impressive heating efficiency and speed. The unique properties of graphene allow for rapid heat transfer and distribution. According to data from Shaanxi Shengxihong Science and Technology Co., Ltd, their graphene heating systems achieve a far-infrared conversion efficiency of up to 83%. This means that a large portion of the electrical energy is converted directly into radiant heat, which is quickly and evenly distributed across the floor surface.

Moreover, the electrothermal conversion efficiency of these systems reaches an astounding 99.8%, minimizing energy waste and ensuring that almost all the input power is transformed into useful heat. This high efficiency translates to faster warm-up times and more consistent temperatures throughout the heated area.

②Traditional Systems: The Lag Factor

In contrast, ordinary underfloor heating systems often suffer from slower response times and less uniform heat distribution. Water-based systems, in particular, can take several hours to reach the desired temperature due to the thermal mass of the water and flooring materials. Electric systems fare somewhat better in terms of response time but may still struggle with even heat distribution, especially in larger spaces.

The lag in heating response can lead to energy waste, as users might overcompensate by setting higher temperatures or leaving the system running for longer periods. Additionally, the uneven heat distribution can result in cold spots and reduced comfort levels.

Energy Consumption

①Graphene's Superior Energy Efficiency

The energy consumption of heating systems is a critical factor for both environmental and economic reasons. Graphene floor heating systems excel in this aspect, thanks to their high conversion efficiencies and rapid heating capabilities. The near-perfect electrothermal conversion rate of 99.8% ensures that virtually all the electrical energy consumed is converted into useful heat.

Furthermore, the quick response time of graphene heating allows for more precise temperature control. Users can heat spaces quickly when needed and easily reduce or turn off the heating when not required, leading to significant energy savings over time. This responsiveness is particularly beneficial in spaces with intermittent use or in regions with variable climates.

②Traditional Systems: The Energy Cost of Inefficiency

Ordinary underfloor heating systems, while generally more efficient than conventional radiators, still face challenges in energy consumption. Water-based systems can suffer from heat loss in the pipes, reducing overall efficiency. They also require energy to pump water through the system, adding to the total energy consumption.

Electric underfloor heating, while simpler in design, may consume more energy due to lower conversion efficiencies and longer warm-up times. The need to maintain a consistent temperature in the face of slower response times can lead to higher energy usage, especially in poorly insulated spaces.

Contact Shaanxi Shengxihong Science and Technology Co., Ltd

Graphene floor heating represents a significant leap forward in heating technology, offering superior performance across multiple dimensions when compared to ordinary underfloor heating systems.

If you're considering upgrading your heating system or are involved in a new construction project, graphene heating film deserves serious consideration. To learn more about how graphene film can benefit your specific needs, reach out to Shaanxi Shengxihong Science and Technology Co., Ltd.'s expert team at 1315363763@qq.com.

References

- Novoselov, K. S., et al. (2012). A roadmap for graphene. Nature, 490(7419), 192-200.

- Huang, X., et al. (2020). Graphene-Based Materials for Efficient Thermal Management. Advanced Materials, 32(8), 1904042.

- Kang, J., et al. (2017). Graphene and graphene-based materials for energy storage and conversion. NPG Asia Materials, 9(6), e388.

- Seo, J. W. T., et al. (2015). Thermal properties of graphene and carbon nanotube composites. ACS Applied Materials & Interfaces, 7(11), 6040-6047.

- Jiang, J. W., et al. (2015). Thermal conductivity of graphene and its polymer nanocomposites: A review. Express Polymer Letters, 9(5), 393-404.