Fabrication Of Graphene Heating Films

2025-09-01 21:01:49

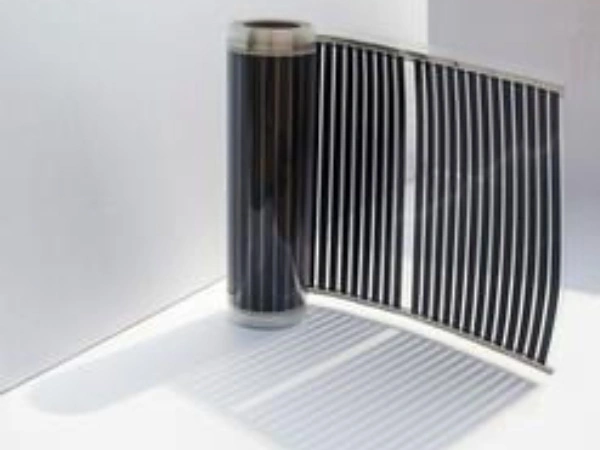

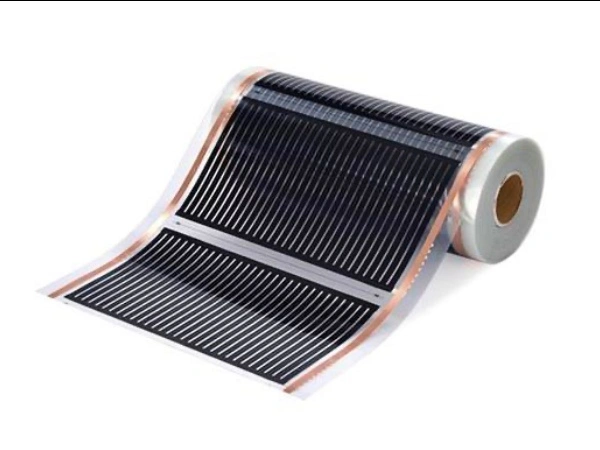

Graphene heating films have revolutionized warm administration over businesses, from private warming to restorative gadgets, by advertising tall electro-thermal transformation effectiveness, adaptability, and uniform warm dissemination. The execution of these movies is profoundly tied to their creation strategies, which decide basic properties such as conductivity, thickness, and solidness. This article gives a comprehensive outline of the essential creation strategies for graphene warming movies, investigating their fundamental standards, handle optimization, and reasonableness for particular applications.

Liquid-Phase Exfoliation and Coating Methods

①Exfoliation of Graphite into Graphene Nanosheets

Liquid-phase peeling (LPE) is a cost-effective strategy for creating graphene nanosheets, the building squares of warming movies. The prepare starts with graphite chips, which are scattered in a dissolvable (e.g., N-methylpyrrolidone, water with surfactants) and subjected to mechanical energy,typically by means of sonication or high-shear blending. Sonication employments ultrasonic waves to make cavitation bubbles, whose collapse produces shear strengths that isolated graphite layers into single or few-layer Graphene heating films. Surfactants (e.g., sodium dodecyl sulfate) or polymers are regularly included to stabilize the exfoliated sheets, anticipating reaggregation by presenting electrostatic or steric repulsion.

Key parameters for LPE incorporate shedding time (1–24 hours), dissolvable sort, and graphite concentration (0.1–10 mg/mL). Longer sonication times increment shedding surrender but may present abandons; optimizing this adjust is basic, as absconds diminish electrical conductivity,a key property for warming movies. Ordinary yields extend from 10–30%, with horizontal sheet sizes of 1–10 μm, appropriate for movies requiring direct conductivity (10³–10⁴ S/m).

②Coating and Film Formation Processes

Once exfoliated, graphene nanosheets are stored onto substrates through coating methods custom fitted to film prerequisites. Shower coating employments a spout to atomize the graphene scattering into fine beads, which are stored onto warmed substrates (50–100°C) to vanish the dissolvable. This strategy empowers large-area statement (up to square meters) with controllable thickness (1–50 μm) and is perfect for adaptable substrates like PET or polyimide. Turn coating, by differentiate, includes dropping the scattering onto a pivoting substrate (1000–5000 rpm), with centrifugal drive spreading the fluid into a uniform film. It produces more slender movies (100 nm–5 μm) with tall consistency, appropriate for accuracy applications like sensor-integrated warming films.

After coating, movies experience post-treatment to upgrade conductivity. Warm tempering (150–300°C in idle gas) expels leftover solvents and surfactants, whereas chemical diminishment (e.g., utilizing hydrazine or ascorbic corrosive) repairs absconds in oxidized graphene sheets. These steps ordinarily increment conductivity by 20–50%, guaranteeing the movies meet the 90%+ electro-thermal transformation effectiveness required for warming applications.

Liquid-phase strategies exceed expectations in versatility and cost-effectiveness, making them prevalent for mass-produced warming movies. Be that as it may, their dependence on exfoliated graphene, with inborn defects,limits execution in high-end applications. For these, vapor-phase union strategies offer prevalent fabric quality, as investigated in the following section.

Vapor-Phase Deposition Techniques

①Chemical Vapor Deposition (CVD) on Catalytic Substrates

Chemical vapor statement (CVD) produces high-quality graphene movies with negligible surrenders, making them perfect for high-performance warming applications. The handle happens in a heater where a catalytic metal substrate (as a rule copper or nickel) is warmed to 800–1100°C beneath a stream of hydrocarbon gasses (e.g., methane, ethylene). Hydrocarbons break down at tall temperatures, discharging carbon iotas that break up into the metal and accelerate as graphene layers upon cooling. Copper, a surface catalyst, regularly yields monolayer graphene, whereas nickel,with higher carbon solvency, produces multilayer films.

CVD parameters are firmly controlled to optimize film quality: gas stream rates (10–100 sccm), weight (0.1–10 Torr), and cooling rate (1–10°C/s) decide crystallinity and space estimate. Moderate cooling, for illustration, advances bigger space sizes (>100 μm), improving conductivity (up to 10⁵ S/m). After blend, the Graphene heating films are exchanged to a target substrate (e.g., glass, polymers) by carving the metal catalyst with FeCl₃ or ammonium persulfate, a sensitive step that requires care to maintain a strategic distance from tearing.

②Plasma-Enhanced CVD (PECVD) for Low-Temperature Deposition

Plasma-enhanced CVD (PECVD) expands vapor-phase testimony to temperature-sensitive substrates (e.g., plastics) by utilizing plasma to enact hydrocarbon forerunners, diminishing required temperatures to 200–600°C. A radiofrequency (RF) or microwave plasma source ionizes gasses (e.g., methane and hydrogen), producing responsive species (particles, radicals) that drive graphene development without tall warm vitality. PECVD movies have marginally higher deformity densities than ordinary CVD movies but offer superior attachment to non-metal substrates, making them reasonable for adaptable warming movies coordinates into clothing or restorative wraps.

Plasma control (50–500 W) and forerunner proportion (CH₄:H₂ = 1:10 to 1:100) are key factors: higher control increments plasma thickness, quickening development but possibly presenting absconds. PECVD movies regularly display conductivities of 10⁴–10⁵ S/m, adjusting execution with testimony versatility.

Vapor-phase strategies deliver the highest-quality graphene warming movies but at higher taken a toll due to specialized hardware and complex exchange steps. For applications requiring a adjust of execution and handle straightforwardness, crossover manufacture approaches,combining components of fluid and vapor strategies, offer compelling solutions.

Hybrid and Post-Fabrication Optimization

①Composite Film Fabrication with Binders and Additives

Hybrid manufacture combines graphene with polymers, metals, or ceramics to upgrade mechanical quality or tailor conductivity. In one common approach, graphene nanosheets (from LPE) are blended with a polymer folio (e.g., polyurethane, epoxy) in a dissolvable, shaping a composite scattering. This blend is coated onto substrates by means of edge coating or plunge coating, with the polymer official graphene sheets into a adaptable film. Cover substance (5–20 wt%) is basic: as well much decreases conductivity, whereas as well small compromises adaptability. Metal added substances (e.g., silver nanoparticles) can advance boost conductivity by shaping conductive pathways between graphene sheets, in spite of the fact that at the taken a toll of expanded fabric expense.

②Post-Treatment for Performance Enhancement

Post-fabrication medications are fundamental for maximizing warming film execution. Mechanical compression (applying 1–10 MPa weight) moves forward inter-sheet contact, diminishing resistance by 10–30%. Laser toughening employments centered laser bars (wavelength 532–1064 nm) to specifically warm Graphene heating films, evacuating abandons and moving forward crystallinity without harming the substrate. This strategy can increment conductivity by up to 40% in LPE movies, bridging the execution hole with CVD films. Electrical conditioning,cycling the film through voltage ranges (5–20 V) for 1–10 hours, too stabilizes execution, diminishing control constriction over time. This step is basic for warming movies utilized in long-term applications like underfloor warming, where reliable yield is essential.

③Quality Control and Testing Protocols

Quality control guarantees created movies meet application prerequisites. Key tests incorporate four-point test estimations for conductivity, infrared thermography to evaluate warming consistency, and cyclic twisting tests (10,000+ cycles) to assess adaptability. For safety-critical applications (e.g., restorative gadgets), tests for waterproofing (IP rating) and dielectric quality (resistance to breakdown beneath tall voltage) are obligatory. Adherence to guidelines such as ASTM D4496 (for electrical conductivity) and ISO 18788 (for adaptable materials) guarantees consistency over generation batches.

Conclusion

The manufacture of Graphene heating films is a nuanced prepare, with each technique,liquid-phase peeling, vapor-phase statement, and half breed methods,offering unmistakable trade-offs between fetched, execution, and adaptability. Liquid-phase strategies overwhelm mass generation for cost-sensitive applications, whereas vapor-phase strategies exceed expectations in high-performance scenarios. Cross breed approaches and post-treatment optimization assist extend the flexibility of these movies, empowering customization for differing employments from private warming to wearable innovation. As creation strategies proceed to advance,with changes in imperfection control and scaling, graphene warming movies are balanced to supplant conventional warming arrangements in an expanding run of applications, driven by their predominant effectiveness and adaptability.

Shengxihong Science and Innovation Co., Ltd, working beneath the brand "Shengxihong", specializes in the advancement, generation, and deal of a different extend of graphene-based items, counting graphene sauna rooms, cold-resistant air-conditioners, electric warming movies, electric warming works of art, electric radiators, physical treatment clothing, electric covers, and car shrewdly warming situate pads. All offerings are supported by free mental property rights and licenses, with the company holding 17 graphene utility demonstrate licenses and over 30 privileged certificates at different levels. For request, contact by means of mail: 1315363763@qq.com.

References

- Allen, M. J., et al. (2010). "Liquid exfoliation of graphene." Small, 6(8), 881–890.

- Bae, S., et al. (2010). "Roll-to-roll production of 30-inch graphene films for transparent electrodes." Nature Nanotechnology, 5(8), 574–578.

- Chhowalla, M., et al. (2010). "The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets." Nature Chemistry, 2(11), 1010–1022.

- Li, X., et al. (2018). "Large-area synthesis of graphene films for electronic devices." Advanced Materials, 30(4), 1703792.

- Zhang, H., et al. (2021). "Hybrid graphene films for flexible heating applications: Fabrication and performance." Composites Science and Technology, 207, 108768.