Electrochemistry For Growing Graphene Heating Film

2025-09-01 21:01:48

Graphene heating films have developed as a transformative innovation in warm administration, esteemed for their tall electro-thermal transformation effectiveness, uniform warming, and adaptability. Whereas chemical vapor statement (CVD) and mechanical shedding overwhelm graphene amalgamation, electrochemistry offers a versatile, low-cost elective for developing graphene movies custom fitted for warming applications. This article investigates the part of electrochemistry in synthesizing graphene warming movies, specifying the basic instruments, key handle parameters, and coming about fabric properties that make these movies reasonable for warming technologies.

Electrochemical Mechanisms of Graphene Growth

①Electrochemical Reduction and Nucleation

Electrochemical union of graphene warming movies essentially depends on the lessening of carbon-containing antecedents, most commonly graphene oxide (GO) scatterings, in an electrolyte arrangement. The handle happens in an electrochemical cell with a working anode (substrate for film testimony), a counter cathode (frequently platinum or graphite), and a reference anode (e.g., Ag/AgCl). When a controlled voltage or current is connected, electrons are exchanged to GO sheets at the working cathode surface, activating the diminishment of oxygen-containing useful bunches (epoxy, hydroxyl, carboxyl). This decrease reestablishes sp² carbon holding systems, a basic step for creating the electrical conductivity required for warming applications.

Nucleation,the introductory arrangement of Graphene heating films, is a key component in electrochemical development. Diminished GO (rGO) sheets total at the cathode surface, driven by electrostatic intelligent between charged utilitarian bunches and the electrode's potential. Over time, these spaces blend to frame nonstop movies, with the nucleation rate controlled by the connected potential: higher possibilities quicken lessening, driving to speedier nucleation but possibly littler space sizes, whereas lower possibilities advance bigger, more requested domains.

②Precursor Chemistry and Electrolyte Roles

The choice of antecedent and electrolyte essentially impacts film quality. GO, synthesized through chemical oxidation of graphite, is the most common forerunner due to its water solvency and ease of handling. Its concentration in the electrolyte (ordinarily 0.1–1 mg/mL) influences film thickness: higher concentrations lead to thicker movies but may present absconds from inadequate diminishment. Electrolytes, such as fluid arrangements of Na₂SO₄ or KCl (0.1–0.5 M), give ionic conductivity, empowering proficient electron exchange between terminals. A few electrolytes too act as catalysts: for illustration, cations like Li⁺ or Mg²⁺ can facilitate with GO's oxygen bunches, improving diminishment productivity and advancing smoother film formation.

Alternative antecedents, such as glucose or sucrose, are utilized in "green" electrochemical amalgamation, where carbon sources are decreased straightforwardly to graphene without earlier oxidation. This strategy maintains a strategic distance from unforgiving chemicals but requires higher temperatures (60–90°C) to drive carbonization, coming about in movies with higher imperfection densities,still practical for warming applications where crystallinity is less basic than cost-effectiveness.

Understanding these electrochemical mechanisms,reduction, nucleation, and antecedent intelligent, lays the establishment for optimizing union forms. The following area investigates how handle parameters can be tuned to upgrade the properties of Graphene heating films.

Process Parameters and Their Impact on Film Properties

①Voltage, Current, and Deposition Time

Electrochemical parameters straightforwardly control film conductivity, a key metric for warming execution. Connected voltage (regularly -0.5 to -2.0 V vs. Ag/AgCl) decides the lessening degree: voltages more negative than -1.5 V quicken diminishment but may cause over-reduction, presenting auxiliary surrenders (e.g., opening) that decrease conductivity. Current thickness (0.1–1 mA/cm²) offers superior control over testimony rate, with lower densities creating more uniform movies. Statement time (10–60 minutes) directs film thickness, with a straight relationship watched in most systems,10 minutes yielding ~100 nm movies, 30 minutes ~300 nm. Thicker movies improve warming control but require higher voltages to keep up effectiveness, adjusting between warm yield and vitality consumption.

②Temperature and Substrate Effects

Electrolyte temperature impacts both response energy and film morphology. Lifted temperatures (40–60°C) increment antecedent dissemination rates, advancing uniform film scope and diminishing pinholes. In any case, temperatures over 70°C can cause antecedent debasement, especially for GO, driving to expanded deformity thickness. Substrate choice is similarly basic: conductive substrates like copper, nickel, or indium tin oxide (ITO) guarantee effective electron exchange, whereas protection substrates (e.g., glass, polymers) require a conductive seed layer (e.g., sputtered gold) to start statement. Adaptable substrates like polyethylene terephthalate (PET) are favored for warming movies, as electrochemical statement at moo temperatures (25–40°C) maintains a strategic distance from substrate deformation.

③Post-Treatment for Enhanced Performance

Post-deposition medications regularly progress film properties. Warm tempering (150–300°C in idle gas) expels remaining water and unstable byproducts, reinforcing sp² holding and expanding conductivity by 20–50%. Chemical doping, utilizing acids (e.g., HNO₃) or metals (e.g., silver nanoparticles), assist improves conductivity by presenting charge carriers. For illustration, tempering rGO movies at 200°C for 2 hours increments their electro-thermal change proficiency from ~85% to ~92%, a basic enhancement for warming applications where vitality squander must be minimized.

By optimizing these parameters,voltage, temperature, substrate, and post-treatment, electrochemical blend can deliver Graphene heating films with custom fitted properties for warming. The taking after area looks at how these movies perform in down to earth warming applications and their points of interest over alternatives.

Performance Metrics and Applications in Heating Technologies

①Electro-Thermal Efficiency and Heating Uniformity

Electrochemically developed Graphene heating films display amazing electro-thermal transformation efficiencies, regularly 85–95%, rivaling CVD-grown movies. This proficiency emerges from the reestablished sp² systems, which empower productive electron-phonon coupling (the component by which electrical vitality changes over to warm). Testing appears that a 10 cm × 10 cm film (300 nm thick) working at 12 V comes to 60°C inside 2 minutes, with a control thickness of 150–200 W/m²,sufficient for private or commercial heating.

Heating uniformity is another strength, with temperature variations across the film surface typically <3°C. This uniformity stems from the film's continuous structure, as electrochemical deposition minimizes agglomeration or voids that cause hotspots. In contrast, films synthesized via solution casting often have higher variability (>5°C) due to uneven drying.

②Durability and Flexibility for Practical Use

After 10,000 hours of operation, accelerated aging tests reveal less than 5% power attenuation, demonstrating the exceptional endurance of electrochemical coatings.They are appropriate for curved surfaces like heating pads or car seat heaters because of their flexibility, which allows them to sustain 10,000 bending cycles (radius of 5 mm) without losing functionality. Because graphene sheets are densely packed, the films are also resistant to moisture and corrosion, negating the need for further protective coatings.

③Scalability and Cost Advantages

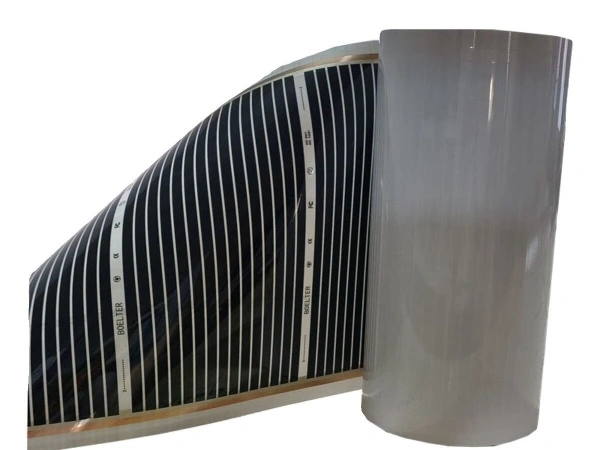

With roll-to-roll deposition devices, electrochemical synthesis may easily scale to large-area films (1 m² or more) and is around 30% less expensive to produce than CVD techniques. Because water-based electrolytes are used instead of costly vacuum equipment or hydrocarbon gases, and because ambient pressure and moderate temperatures result in lower energy requirements, this cost-effectiveness is achieved. Graphene heating films are now competitive with traditional resistive heating mats thanks to these revolutionary savings for high-volume applications like underfloor heating.

Conclusion

Utilizing reduction processes, adjustable process settings, and affordable precursors, electrochemistry provides a flexible, scalable method for creating Graphene heating films with excellent electro-thermal efficiency, homogeneity, and durability. Researchers and producers can modify these films to satisfy the requirements of various heating applications, ranging from portable heating devices to home underfloor systems, by adjusting voltage, temperature, and precursor chemistry.With advancements in scalability and defect control, electrochemical techniques are well-positioned to propel the wider adoption of graphene heating technology and provide a sustainable substitute for traditional heating methods.

Shengxihong Science and Technology Co., Ltd develops, produces and sells the following products: Graphene sauna room, Graphene cold-resistant air-conditioner, Graphene electric heating film, Graphene electric heating painting, Graphene electric heater, Graphene physical therapy clothing, Graphene electric blanket, and Graphene car intelligent heating seat cushion under the brand name of "Shengxihong". All the products listed for sale have independent intellectual property rights and patents. The company has obtained 17 graphene utility model patents and won more than 30 honorary certificates at all levels. Contact email: 1315363763@qq.com.

References

- Wang, Y., et al. (2020). "Electrochemical synthesis of graphene films for flexible heating applications: Mechanisms and optimization." Electrochimica Acta, 349, 136352.

- Li, J., & Zhang, H. (2019). "Electrochemical reduction of graphene oxide: A review on parameters control and applications in energy storage." Journal of Electroanalytical Chemistry, 849, 113358.

- Chen, L., et al. (2021). "Large-area graphene heating films synthesized via roll-to-roll electrochemical deposition: Performance and scalability." Thin Solid Films, 723, 138521.

- Park, S., et al. (2018). "Effect of electrolyte composition on the properties of electrochemically grown graphene films for thermal management." Materials Chemistry and Physics, 210, 136–143.