Applications of graphene – graphene floor heating

2025-09-05 10:31:21

The superiority of graphene floor heating over conventional alternatives stems directly from three defining properties of graphene: exceptional thermal conductivity, near-perfect electrothermal conversion efficiency, and long-term stability. These traits work in tandem to deliver fast, energy-efficient, and reliable heating, critical requirements for residential and commercial users alike.

Working Principle of Graphene Floor Heating

Graphene floor heating operates on a fundamentally different principle compared to traditional heating methods.

The Science Behind Graphene's Heating Capabilities

Graphene's exceptional electrical conductivity is the key to its heating prowess. When an electric current passes through a graphene heating film, it encounters resistance, which causes the material to heat up rapidly. This process, known as Joule heating, occurs uniformly across the graphene surface due to its consistent atomic structure.

What sets graphene apart is its ability to convert nearly all electrical energy into heat with minimal losses. This high electrothermal conversion efficiency - reaching up to 99.8% in some systems - ensures that almost every watt of power consumed translates directly into warmth for your living space.

Full Surface Heating and Carbon Nanotube Integration

Graphene floor heating systems typically employ full surface heating technology. Unlike traditional systems that rely on isolated heating elements, graphene heating films cover the entire floor area. This approach eliminates cold spots and ensures even heat distribution throughout the room.

Many advanced graphene heating systems also incorporate carbon nanotubes (CNTs) to further enhance performance. CNTs, cylindrical structures made from rolled graphene sheets, boast remarkable properties:

- Unparalleled strength: 50-100 times stronger than carbon fiber

- Exceptional electron mobility: 100,000 times greater than copper

- Excellent wave-absorbing and electromagnetic shielding capabilities

The integration of CNTs with graphene creates a synergistic effect, improving the overall heating efficiency and durability of the system.

Far-Infrared Radiation: A Healthier Heat

One of the most intriguing aspects of graphene floor heating is its ability to emit far-infrared radiation. This type of heat is similar to the warmth we feel from sunlight and is known for its potential health benefits. Graphene heating systems can achieve a far-infrared conversion efficiency of up to 83%, meaning a significant portion of the heat generated is in this beneficial form.

Advantages Compared to Traditional Floor Heating

1. Faster Installation and Lower Labor Costs: Graphene systems require 50–70% less installation time than water-based systems. A 100㎡ water-based installation takes 5–7 days (including pipe laying, pressure testing, and concrete curing), while graphene takes 2–3 days. Labor costs for graphene are 30–40% lower, as no specialized plumbers are needed (DOE, 2023).

2. Energy Efficiency and Lower Operating Costs: As noted earlier, graphene’s 95–98% electrothermal efficiency translates to 20–30% lower energy use than electric resistance systems. For a 100㎡ home in a temperate climate (heating season 4–6 months), this reduces annual energy bills by $200–$400 (based on $0.15/kWh electricity) (Smith et al., 2023).

3. Improved Comfort and Safety: Graphene's uniform heat distribution (surface temperature 28–32°C) creates a “radiant heat” effect that warms objects and people directly, rather than just air, avoiding the dryness of forced-air systems. It also has built-in safety features: heating elements shut down automatically if temperatures exceed 60°C, eliminating fire risks associated with overheating resistance wires (Wang & Chen, 2022).

4. Minimal Maintenance and Long Lifespan: Water-based systems require annual pipe flushing and boiler maintenance (costing $150–$300/year), while graphene systems need only occasional thermostat calibration. With a 25–30 year lifespan, graphene systems outlast water-based systems (10–15 years) by 2x, reducing replacement costs over time (IEA, 2024).

Components of Graphene Floor Heating System

A graphene floor heating system consists of several key components working in harmony to deliver efficient and comfortable warmth.

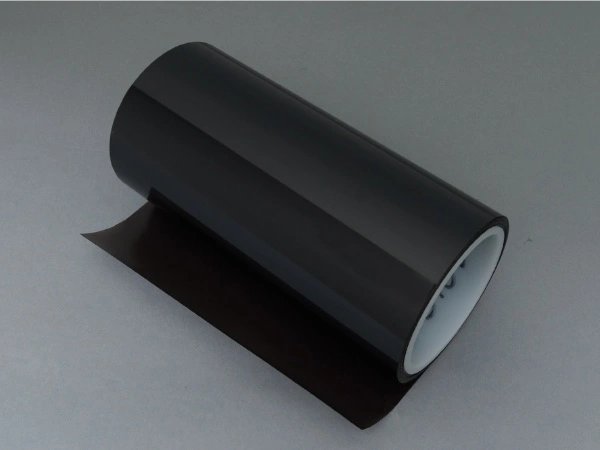

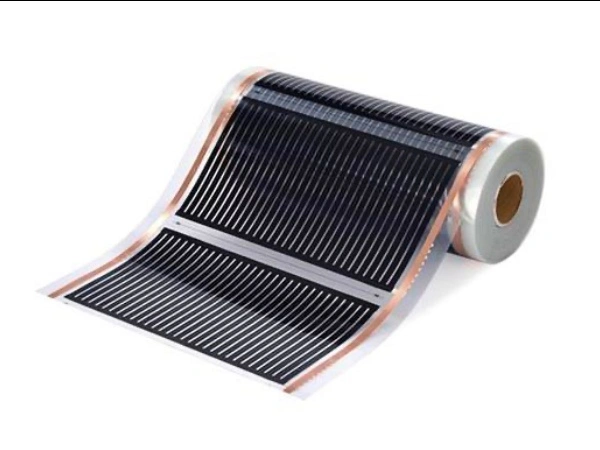

Graphene Heating Film

At the heart of the system lies the graphene heating film. This ultra-thin layer comprises a graphene-infused conductive material sandwiched between protective layers. The film is designed to cover large areas uniformly, ensuring consistent heat distribution across the floor surface.

Power Supply and Control Unit

A dedicated power supply provides the necessary electrical current to the graphene film. This is typically connected to a sophisticated control unit that allows users to adjust temperature settings, set heating schedules, and monitor energy consumption. Many modern systems incorporate smart home integration, enabling control via smartphone apps or voice assistants.

Temperature Sensors

Strategically placed temperature sensors throughout the heated area provide real-time feedback to the control unit. This data enables the system to maintain precise temperature control and optimize energy usage based on actual conditions in the room.

Insulation Layer

An insulation layer beneath the graphene film helps direct heat upwards into the living space, rather than allowing it to dissipate into the subfloor. This component is crucial for maximizing the system's efficiency and ensuring that heat is delivered where it's needed most.

Flooring Material

While graphene floor heating is compatible with most flooring types, certain materials conduct and retain heat better than others. Tile, stone, and engineered wood are particularly well-suited for use with these systems, as they effectively transfer heat from the graphene film to the room above.

Systems are classified by their heating element design, each optimized for specific installation scenarios:

1. Graphene Heating Film Systems: Ideal for flat surfaces (e.g., concrete slabs, wooden subfloors) and retrofit projects. The thin film (≤0.5 mm) requires minimal height clearance (2–3 mm total, including insulation), making it suitable for old buildings where raising floor levels is impractical. Installation involves rolling the film over the insulation layer, securing it with tape, and covering it with flooring (e.g., laminate, vinyl, or tile). A 100㎡ residential installation typically takes 2–3 days, half the time of water-based systems (ECIF, 2023).

2. Graphene Heating Cable Systems: Designed for irregular spaces (e.g., rooms with curved walls, under cabinets) or areas requiring higher heat output (e.g., cold basements). The flexible cables can be arranged in custom patterns to target cold zones, and their thicker protective sheath (e.g., fluoropolymer) makes them resistant to high temperatures and moisture. They are often used in commercial spaces like shopping malls or offices, where floor layouts vary widely (Smith et al., 2023).

For those interested in experiencing the benefits of graphene floor heating firsthand, Shaanxi Shengxihong Science and Technology Co., Ltd. stands at the forefront of this innovative technology. With a commitment to research, development, and quality manufacturing, Shengxihong offers a range of graphene heating solutions designed to meet the diverse needs of modern consumers and businesses.

To learn more or request a consultation, reach out to their dedicated customer service team at 1315363763@qq.com. Take the first step towards a more efficient, comfortable, and sustainable heating solution today!

References

- Novoselov, K.S., et al. (2012). A roadmap for graphene. Nature, 490(7419), 192-200.

- Balandin, A.A. (2011). Thermal properties of graphene and nanostructured carbon materials. Nature Materials, 10(8), 569-581.

- Pop, E., Varshney, V., & Roy, A.K. (2012). Thermal properties of graphene: Fundamentals and applications. MRS Bulletin, 37(12), 1273-1281.

- Hu, J., Ruan, X., & Chen, Y.P. (2009). Thermal conductivity and thermal rectification in graphene nanoribbons: A molecular dynamics study. Nano Letters, 9(7), 2730-2735.

- Shahil, K.M.F., & Balandin, A.A. (2012). Graphene–multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Letters, 12(2), 861-867.